Page 279 - Tribology in Machine Design

P. 279

264 Tribology in machine design

contact. At higher speeds, centrifugal effects starve this critical contact of

lubricant.

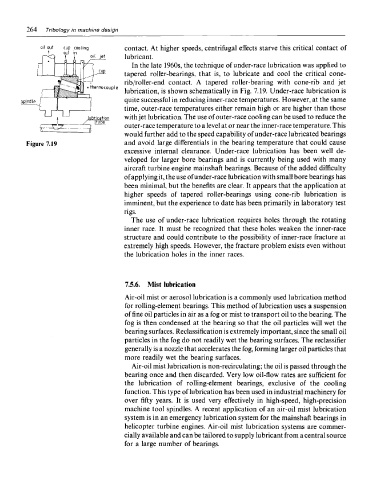

In the late 1960s, the technique of under-race lubrication was applied to

tapered roller-bearings, that is, to lubricate and cool the critical cone-

rib/roller-end contact. A tapered roller-bearing with cone-rib and jet

lubrication, is shown schematically in Fig. 7.19. Under-race lubrication is

quite successful in reducing inner-race temperatures. However, at the same

time, outer-race temperatures either remain high or are higher than those

with jet lubrication. The use of outer-race cooling can be used to reduce the

outer-race temperature to a level at or near the inner-race temperature. This

would further add to the speed capability of under-race lubricated bearings

Figure 7.19 and avoid large differentials in the bearing temperature that could cause

excessive internal clearance. Under-race lubrication has been well de-

veloped for larger bore bearings and is currently being used with many

aircraft turbine engine mainshaft bearings. Because of the added difficulty

of applying it, the use of under-race lubrication with small bore bearings has

been minimal, but the benefits are clear. It appears that the application at

higher speeds of tapered roller-bearings using cone-rib lubrication is

imminent, but the experience to date has been primarily in laboratory test

rigs.

The use of under-race lubrication requires holes through the rotating

inner race. It must be recognized that these holes weaken the inner-race

structure and could contribute to the possibility of inner-race fracture at

extremely high speeds. However, the fracture problem exists even without

the lubrication holes in the inner races.

7.5.6. Mist lubrication

Air-oil mist or aerosol lubrication is a commonly used lubrication method

for rolling-element bearings. This method of lubrication uses a suspension

of fine oil particles in air as a fog or mist to transport oil to the bearing. The

fog is then condensed at the bearing so that the oil particles will wet the

bearing surfaces. Reclassification is extremely important, since the small oil

particles in the fog do not readily wet the bearing surfaces. The reclassifier

generally is a nozzle that accelerates the fog, forming larger oil particles that

more readily wet the bearing surfaces.

Air-oil mist lubrication is non-recirculating; the oil is passed through the

bearing once and then discarded. Very low oil-flow rates are sufficient for

the lubrication of rolling-element bearings, exclusive of the cooling

function. This type of lubrication has been used in industrial machinery for

over fifty years. It is used very effectively in high-speed, high-precision

machine tool spindles. A recent application of an air-oil mist lubrication

system is in an emergency lubrication system for the mainshaft bearings in

helicopter turbine engines. Air-oil mist lubrication systems are commer-

cially available and can be tailored to supply lubricant from a central source

for a large number of bearings.