Page 284 - Tribology in Machine Design

P. 284

Rolling-contact bearings 269

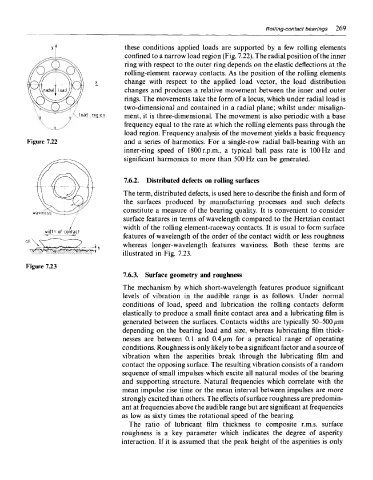

these conditions applied loads are supported by a few rolling elements

confined to a narrow load region (Fig. 7.22). The radial position of the inner

ring with respect to the outer ring depends on the elastic deflections at the

rolling-element raceway contacts. As the position of the rolling elements

change with respect to the applied load vector, the load distribution

changes and produces a relative movement between the inner and outer

rings. The movements take the form of a locus, which under radial load is

two-dimensional and contained in a radial plane; whilst under misalign-

ment, it is three-dimensional. The movement is also periodic with a base

frequency equal to the rate at which the rolling elements pass through the

load region. Frequency analysis of the movement yields a basic frequency

Figure 7.22 and a series of harmonics. For a single-row radial ball-bearing with an

inner-ring speed of ISOOr.p.m., a typical ball pass rate is 100 Hz and

significant harmonics to more than 500 Hz can be generated.

7.6.2. Distributed defects on rolling surfaces

The term, distributed defects, is used here to describe the finish and form of

the surfaces produced by manufacturing processes and such defects

constitute a measure of the bearing quality. It is convenient to consider

surface features in terms of wavelength compared to the Hertzian contact

width of the rolling element-raceway contacts. It is usual to form surface

features of wavelength of the order of the contact width or less roughness

whereas longer-wavelength features waviness. Both these terms are

illustrated in Fig. 7.23.

Figure 7.23

7.6.3. Surface geometry and roughness

The mechanism by which short-wavelength features produce significant

levels of vibration in the audible range is as follows. Under normal

conditions of load, speed and lubrication the rolling contacts deform

elastically to produce a small finite contact area and a lubricating film is

generated between the surfaces. Contacts widths are typically 50-500 jum

depending on the bearing load and size, whereas lubricating film thick-

nesses are between 0.1 and 0.4 nm for a practical range of operating

conditions. Roughness is only likely to be a significant factor and a source of

vibration when the asperities break through the lubricating film and

contact the opposing surface. The resulting vibration consists of a random

sequence of small impulses which excite all natural modes of the bearing

and supporting structure. Natural frequencies which correlate with the

mean impulse rise time or the mean interval between impulses are more

strongly excited than others. The effects of surface roughness are predomin-

ant at frequencies above the audible range but are significant at frequencies

as low as sixty times the rotational speed of the bearing.

The ratio of lubricant film thickness to composite r.m.s. surface

roughness is a key parameter which indicates the degree of asperity

interaction. If it is assumed that the peak height of the asperities is only