Page 23 - Troubleshooting Analog Circuits

P. 23

IO I. First Things First

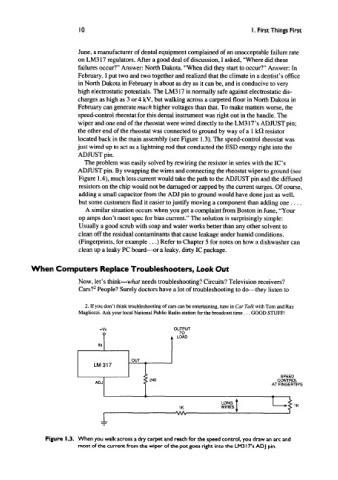

June, a manufacturer of dental equipment complained of an unacceptable failure rate

on LM317 regulators. After a good deal of discussion, I asked, “Where did these

failures occur?” Answer: North Dakota. “When did they start to occur?” Answer: In

February. I put two and two together and realized that the climate in a dentist’s office

in North Dakota in February is about as dry as it can be, and is conducive to very

high electrostatic potentials. The LM3 17 is normally safe against electrostatic dis-

charges as high as 3 or 4 kV, but walking across a carpeted floor in North Dakota in

February can generate much higher voltages than that. To make matters worse, the

speed-control rheostat for this dental instrument was right out in the handle. The

wiper and one end of the rheostat were wired directly to the LM317’s ADJUST pin;

the other end of the rheostat was connected to ground by way of a 1 kfl resistor

located back in the main assembly (see Figure 1.3). The speed-control rheostat was

just wired up to act as a lightning rod that conducted the ESD energy right into the

ADJUST pin.

The problem was easily solved by rewiring the resistor in series with the IC’s

ADJUST pin. By swapping the wires and connecting the rheostat wiper to ground (see

Figure 1.4), much less current would take the path to the ADJUST pin and the diffused

resistors on the chip would not be damaged or zapped by the current surges. Of course,

adding a small capacitor from the ADJ pin to ground would have done just as well,

but some customers find it easier to justify moving a component than adding one . . . .

A similar situation occurs when you get a complaint from Boston in June, “Your

op amps don’t meet spec for bias current.” The solution is surprisingly simple:

Usually a good scrub with soap and water works better than any other solvent to

clean off the residual contaminants that cause leakage under humid conditions.

(Fingerprints, for example. . .) Refer to Chapter 5 for notes on how a dishwasher can

clean up a leaky PC board-r a leaky, dirty IC package.

When Computers Replace Troubleshooters, Look Our

Now, let’s think-what needs troubleshooting? Circuits? Television receivers?

Cars?* People? Surely doctors have a lot of troubleshooting to dethey listen to

2. If you don’t think troubleshooting of cars can be entertaining, tune in Car Talk with Tom and Ray

Magliozzi. Ask your local National Public Radio station for the broadcast time . . . GOOD STUFF!

SPEED

CONTROL

AT FINGERTIPS

1K WIRES I

I %

Figure I .3. When you walk across a dry carpet and reach for the speed control, you draw an arc and

most of the current from the wiper of the pot goes right into the LM3 17’s AD] pin.