Page 145 - Understanding Flight

P. 145

CH05_Anderson 7/25/01 8:58 AM Page 132

132 CHAPTER FIVE

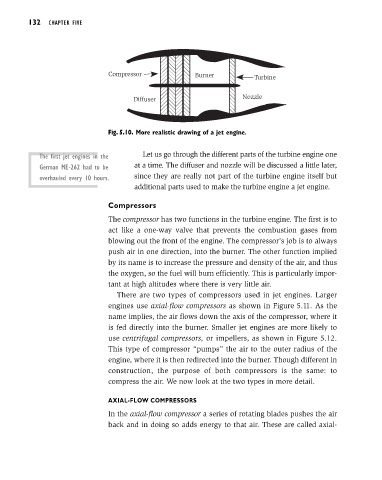

Compressor Burner Turbine

Diffuser Nozzle

Fig. 5.10. More realistic drawing of a jet engine.

The first jet engines in the Let us go through the different parts of the turbine engine one

German ME-262 had to be at a time. The diffuser and nozzle will be discussed a little later,

overhauled every 10 hours. since they are really not part of the turbine engine itself but

additional parts used to make the turbine engine a jet engine.

Compressors

The compressor has two functions in the turbine engine. The first is to

act like a one-way valve that prevents the combustion gases from

blowing out the front of the engine. The compressor’s job is to always

push air in one direction, into the burner. The other function implied

by its name is to increase the pressure and density of the air, and thus

the oxygen, so the fuel will burn efficiently. This is particularly impor-

tant at high altitudes where there is very little air.

There are two types of compressors used in jet engines. Larger

engines use axial-flow compressors as shown in Figure 5.11. As the

name implies, the air flows down the axis of the compressor, where it

is fed directly into the burner. Smaller jet engines are more likely to

use centrifugal compressors, or impellers, as shown in Figure 5.12.

This type of compressor “pumps” the air to the outer radius of the

engine, where it is then redirected into the burner. Though different in

construction, the purpose of both compressors is the same: to

compress the air. We now look at the two types in more detail.

AXIAL-FLOW COMPRESSORS

In the axial-flow compressor a series of rotating blades pushes the air

back and in doing so adds energy to that air. These are called axial-