Page 25 - Valve Selection Handbook

P. 25

12 Valve Selection Handbook

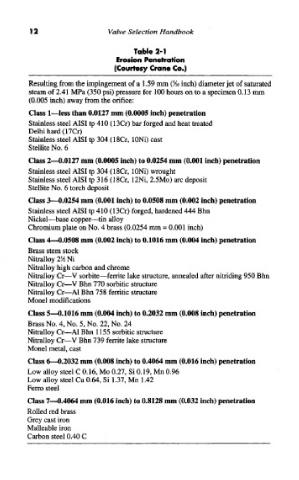

Table 2-1

Erosion Penetration

(Courtesy Crane Co.)

Resulting from the impingement of a 1.59 mm (V\f> inch) diameter jet of saturated

steam of 2.41 MPa (350 psi) pressure for 100 hours on to a specimen 0.13 mm

(0.005 inch) away from the orifice:

Class 1—less than 0.0127 mm (0.0005 inch) penetration

Stainless steel AISI tp 410 (13Cr) bar forged and heat treated

Delhi hard (17Cr)

Stainless steel AISI tp 304 (18Cr, lONi) cast

Stellite No. 6

Class 2—0.0127 mm (0.0005 inch) to 0.0254 mm (0.001 inch) penetration

Stainless steel AISI tp 304 (18Cr, lONi) wrought

Stainless steel AISI tp 316 (18Cr, 12Ni, 2.5Mo) arc deposit

Stellite No. 6 torch deposit

Class 3—0.0254 mm (0.001 inch) to 0.0508 mm (0.002 inch) penetration

Stainless steel AISI tp 410 (13Cr) forged, hardened 444 Bhn

Nickel—base copper—tin alloy

Chromium plate on No. 4 brass (0.0254 mm = 0.001 inch)

Class 4—0.0508 mm (0.002 inch) to 0.1016 mm (0.004 inch) penetration

Brass stem stock

1

2

Nitralloy A Ni

Nitralloy high carbon and chrome

Nitralloy Cr—V sorbite—fertile lake structure, annealed after nitriding 950 Bhn

Nitralloy Cr—V Bhn 770 sorbitic structure

Nitralloy Cr—Al Bhn 758 ferritic structure

Monel modifications

Class 5—0.1016 mm (0.004 inch) to 0.2032 mm (0.008 inch) penetration

Brass No. 4, No. 5, No. 22, No. 24

Nitralloy Cr—Al Bhn 1155 sorbitic structure

Nitralloy Cr—V Bhn 739 ferrite lake structure

Monel metal, cast

Class 6—0.2032 mm (0.008 inch) to 0.4064 mm (0.016 inch) penetration

Low alloy steel C 0.16, Mo 0.27, Si 0.19, Mn 0.96

Low alloy steel Cu 0.64, Si 1.37, Mn 1.42

Ferro steel

Class 7—0.4064 mm (0.016 inch) to 0.8128 mm (0.032 inch) penetration

Rolled red brass

Grey cast iron

Malleable iron

Carbon steel 0.40 C