Page 256 - Valve Selection Handbook

P. 256

Rupture Discs 243

This design encountered two problems. First, the disc would tend to

shear on the sharp edge of the top flange, resulting in unpredictable fail-

ure. Second, as pressure increased, the disc would tend to slip between

the flat faces, resulting in leakage and unpredictable failure.

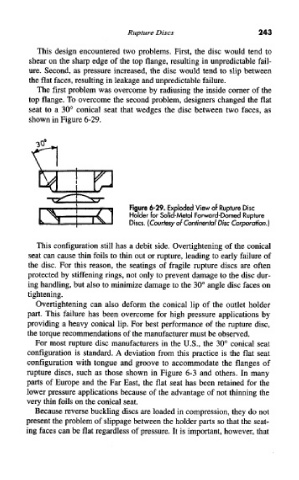

The first problem was overcome by radiusing the inside corner of the

top flange. To overcome the second problem, designers changed the flat

seat to a 30° conical seat that wedges the disc between two faces, as

shown in Figure 6-29.

Figure 6-29. Exploded View of Rupture Disc

Holder for Solid-Metal Forward-Domed Rupture

Discs. (Courtesy of Continental Disc Corporation.

This configuration still has a debit side. Overtightening of the conical

seat can cause thin foils to thin out or rupture, leading to early failure of

the disc. For this reason, the seatings of fragile rupture discs are often

protected by stiffening rings, not only to prevent damage to the disc dur-

ing handling, but also to minimize damage to the 30° angle disc faces on

tightening.

Overtightening can also deform the conical lip of the outlet holder

part. This failure has been overcome for high pressure applications by

providing a heavy conical lip. For best performance of the rupture disc,

the torque recommendations of the manufacturer must be observed.

For most rupture disc manufacturers in the U.S., the 30° conical seat

configuration is standard. A deviation from this practice is the flat seat

configuration with tongue and groove to accommodate the flanges of

rupture discs, such as those shown in Figure 6-3 and others. In many

parts of Europe and the Far East, the flat seat has been retained for the

lower pressure applications because of the advantage of not thinning the

very thin foils on the conical seat.

Because reverse buckling discs are loaded in compression, they do not

present the problem of slippage between the holder parts so that the seat-

ing faces can be flat regardless of pressure. It is important, however, that