Page 253 - Valve Selection Handbook

P. 253

240 Valve Selection Handbook

The graphite commonly used for the manufacture of rupture discs is

the resin-impregnated grade. The material is very brittle and ruptures

almost without deformation. Its structure is very homogeneous and the

strength of the material is low compared with the strength of metals.

Graphite rupture discs are therefore much thicker than metal rupture

discs. This property permits graphite rupture discs to be made to small

burst pressure tolerances.

Pure graphite is a flexible material that is used for the manufacture of

reverse-buckling discs. Because pure graphite is free of resin impregna-

tion, pure graphite rupture discs may be exposed to higher operating tem-

peratures.

Graphite rupture discs may be used in both gas and liquid-full services.

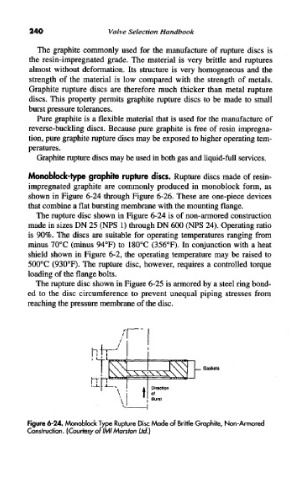

Monoblock-type graphite rupture discs. Rupture discs made of resin-

impregnated graphite are commonly produced in monoblock form, as

shown in Figure 6-24 through Figure 6-26. These are one-piece devices

that combine a flat bursting membrane with the mounting flange.

The rupture disc shown in Figure 6-24 is of non-armored construction

made in sizes DN 25 (NFS 1) through DN 600 (NFS 24). Operating ratio

is 90%. The discs are suitable for operating temperatures ranging from

minus 70°C (minus 94°F) to 180°C (356°F). In conjunction with a heat

shield shown in Figure 6-2, the operating temperature may be raised to

500°C (930°F). The rupture disc, however, requires a controlled torque

loading of the flange bolts.

The rupture disc shown in Figure 6-25 is armored by a steel ring bond-

ed to the disc circumference to prevent unequal piping stresses from

reaching the pressure membrane of the disc.

Figure 6-24. Monoblock Type Rupture Disc Made of Brittle Graphite, Non-Armored

Construction. (Courtesy oflMI Mars/on Ltd.)