Page 94 - Valve Selection Handbook

P. 94

Manual Valves 81

• An electrical drive for wedge gate valves is more complicated than for

parallel gate valves in that the drive must be torque-limited instead of

travel-limited. The operating torque of the drive must thereby be high

enough to effect the wedging of the wedge into the seats while the

valve is being closed against the full differential line pressure. If the

valve is closed against zero differential pressure, the wedging of the

wedge into the seats becomes accordingly higher. To permit the valve to

be opened again against the full differential pressure, and to allow also

for a possible increase of the operating effort due to thermal movements

of the valve parts, the operator must be generously sized.

The limitations of wedge gate valves are otherwise similar to those of

parallel gate valves.

Efforts to improve the performance of wedge gate valves led to the

development of a variety of wedge designs; the most common ones are

described in the following section.

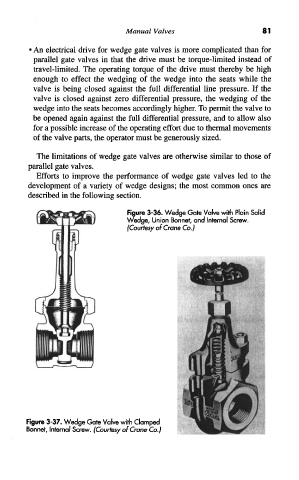

Figure 3-36. Wedge Gate Valve with Plain Solid

Wedge, Union Bonnet, and Internal Screw.

(Courtesy of Crane Co.)

Figure 3-37. Wedge Gate Valve with Clamped

Bonnet, Internal Screw. (Courtesy of Crane Co.)