Page 373 - Materials Chemistry, Second Edition

P. 373

CAT3525_C10.qxd 1/31/2005 12:00 PM Page 344

344 Waste Management Practices: Municipal, Hazardous, and Industrial

Impermeable

cap

Leachate

application

Pump

station

Leachate

Gas collection storage

system tank

Gas

flare

LCR Sump

Geomembrane

Clay

Groundwater

monitoring well

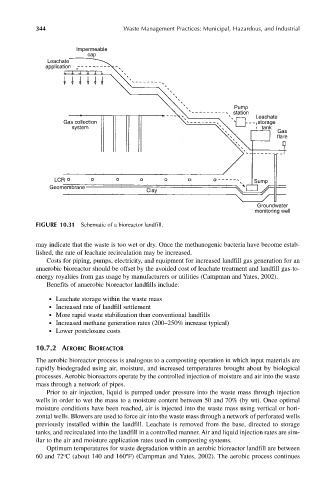

FIGURE 10.31 Schematic of a bioreactor landfill.

may indicate that the waste is too wet or dry. Once the methanogenic bacteria have become estab-

lished, the rate of leachate recirculation may be increased.

Costs for piping, pumps, electricity, and equipment for increased landfill gas generation for an

anaerobic bioreactor should be offset by the avoided cost of leachate treatment and landfill gas-to-

energy royalties from gas usage by manufacturers or utilities (Campman and Yates, 2002).

Benefits of anaerobic bioreactor landfills include:

● Leachate storage within the waste mass

● Increased rate of landfill settlement

● More rapid waste stabilization than conventional landfills

● Increased methane generation rates (200–250% increase typical)

● Lower postclosure costs

10.7.2 AEROBIC BIOREACTOR

The aerobic bioreactor process is analogous to a composting operation in which input materials are

rapidly biodegraded using air, moisture, and increased temperatures brought about by biological

processes. Aerobic bioreactors operate by the controlled injection of moisture and air into the waste

mass through a network of pipes.

Prior to air injection, liquid is pumped under pressure into the waste mass through injection

wells in order to wet the mass to a moisture content between 50 and 70% (by wt). Once optimal

moisture conditions have been reached, air is injected into the waste mass using vertical or hori-

zontal wells. Blowers are used to force air into the waste mass through a network of perforated wells

previously installed within the landfill. Leachate is removed from the base, directed to storage

tanks, and recirculated into the landfill in a controlled manner. Air and liquid injection rates are sim-

ilar to the air and moisture application rates used in composting systems.

Optimum temperatures for waste degradation within an aerobic bioreactor landfill are between

o

60 and 72 C (about 140 and 160ºF) (Campman and Yates, 2002). The aerobic process continues