Page 601 - Materials Chemistry, Second Edition

P. 601

CAT3525_C19.qxd 1/28/2005 5:05 PM Page 572

572 Waste Management Practices: Municipal, Hazardous, and Industrial

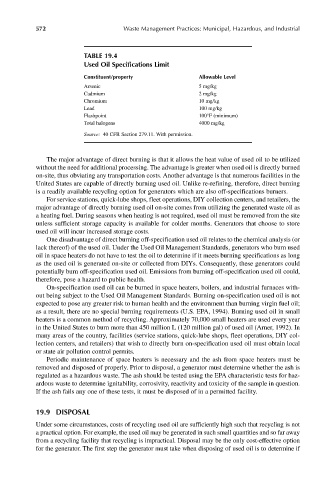

TABLE 19.4

Used Oil Specifications Limit

Constituent/property Allowable Level

Arsenic 5 mg/kg

Cadmium 2 mg/kg

Chromium 10 mg/kg

Lead 100 mg/kg

Flashpoint 100°F (minimum)

Total halogens 4000 mg/kg

Source: 40 CFR Section 279.11. With permission.

The major advantage of direct burning is that it allows the heat value of used oil to be utilized

without the need for additional processing. The advantage is greater when used oil is directly burned

on-site, thus obviating any transportation costs. Another advantage is that numerous facilities in the

United States are capable of directly burning used oil. Unlike re-refining, therefore, direct burning

is a readily available recycling option for generators which are also off-specifications burners.

For service stations, quick-lube shops, fleet operations, DIY collection centers, and retailers, the

major advantage of directly burning used oil on-site comes from utilizing the generated waste oil as

a heating fuel. During seasons when heating is not required, used oil must be removed from the site

unless sufficient storage capacity is available for colder months. Generators that choose to store

used oil will incur increased storage costs.

One disadvantage of direct burning off-specification used oil relates to the chemical analysis (or

lack thereof) of the used oil. Under the Used Oil Management Standards, generators who burn used

oil in space heaters do not have to test the oil to determine if it meets burning specifications as long

as the used oil is generated on-site or collected from DIYs. Consequently, these generators could

potentially burn off-specification used oil. Emissions from burning off-specification used oil could,

therefore, pose a hazard to public health.

On-specification used oil can be burned in space heaters, boilers, and industrial furnaces with-

out being subject to the Used Oil Management Standards. Burning on-specification used oil is not

expected to pose any greater risk to human health and the environment than burning virgin fuel oil;

as a result, there are no special burning requirements (U.S. EPA, 1994). Burning used oil in small

heaters is a common method of recycling. Approximately 70,000 small heaters are used every year

in the United States to burn more than 450 million L (120 million gal) of used oil (Arner, 1992). In

many areas of the country, facilities (service stations, quick-lube shops, fleet operations, DIY col-

lection centers, and retailers) that wish to directly burn on-specification used oil must obtain local

or state air pollution control permits.

Periodic maintenance of space heaters is necessary and the ash from space heaters must be

removed and disposed of properly. Prior to disposal, a generator must determine whether the ash is

regulated as a hazardous waste. The ash should be tested using the EPA characteristic tests for haz-

ardous waste to determine ignitability, corrosivity, reactivity and toxicity of the sample in question.

If the ash fails any one of these tests, it must be disposed of in a permitted facility.

19.9 DISPOSAL

Under some circumstances, costs of recycling used oil are sufficiently high such that recycling is not

a practical option. For example, the used oil may be generated in such small quantities and so far away

from a recycling facility that recycling is impractical. Disposal may be the only cost-effective option

for the generator. The first step the generator must take when disposing of used oil is to determine if