Page 125 - Wastewater Solids Incineration Systems

P. 125

Combustion Technology 93

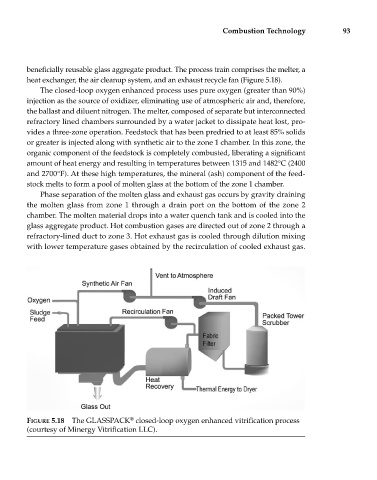

beneficially reusable glass aggregate product. The process train comprises the melter, a

heat exchanger, the air cleanup system, and an exhaust recycle fan (Figure 5.18).

The closed-loop oxygen enhanced process uses pure oxygen (greater than 90%)

injection as the source of oxidizer, eliminating use of atmospheric air and, therefore,

the ballast and diluent nitrogen. The melter, composed of separate but interconnected

refractory lined chambers surrounded by a water jacket to dissipate heat lost, pro-

vides a three-zone operation. Feedstock that has been predried to at least 85% solids

or greater is injected along with synthetic air to the zone 1 chamber. In this zone, the

organic component of the feedstock is completely combusted, liberating a significant

amount of heat energy and resulting in temperatures between 1315 and 1482°C (2400

and 2700°F). At these high temperatures, the mineral (ash) component of the feed-

stock melts to form a pool of molten glass at the bottom of the zone 1 chamber.

Phase separation of the molten glass and exhaust gas occurs by gravity draining

the molten glass from zone 1 through a drain port on the bottom of the zone 2

chamber. The molten material drops into a water quench tank and is cooled into the

glass aggregate product. Hot combustion gases are directed out of zone 2 through a

refractory-lined duct to zone 3. Hot exhaust gas is cooled through dilution mixing

with lower temperature gases obtained by the recirculation of cooled exhaust gas.

®

FIGURE 5.18 The GLASSPACK closed-loop oxygen enhanced vitrification process

(courtesy of Minergy Vitrification LLC).