Page 120 - Wastewater Solids Incineration Systems

P. 120

Combustion Technology 89

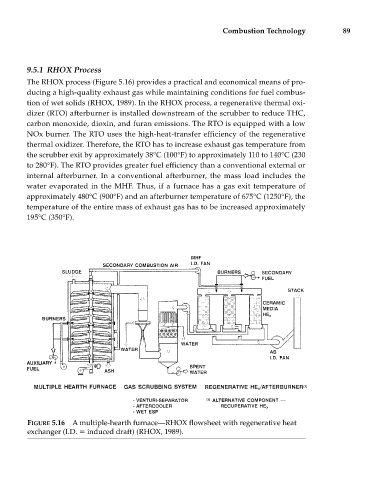

9.5.1 RHOX Process

The RHOX process (Figure 5.16) provides a practical and economical means of pro-

ducing a high-quality exhaust gas while maintaining conditions for fuel combus-

tion of wet solids (RHOX, 1989). In the RHOX process, a regenerative thermal oxi-

dizer (RTO) afterburner is installed downstream of the scrubber to reduce THC,

carbon monoxide, dioxin, and furan emissions. The RTO is equipped with a low

NOx burner. The RTO uses the high-heat-transfer efficiency of the regenerative

thermal oxidizer. Therefore, the RTO has to increase exhaust gas temperature from

the scrubber exit by approximately 38°C (100°F) to approximately 110 to 140°C (230

to 280°F). The RTO provides greater fuel efficiency than a conventional external or

internal afterburner. In a conventional afterburner, the mass load includes the

water evaporated in the MHF. Thus, if a furnace has a gas exit temperature of

approximately 480°C (900°F) and an afterburner temperature of 675°C (1250°F), the

temperature of the entire mass of exhaust gas has to be increased approximately

195°C (350°F).

FIGURE 5.16 A multiple-hearth furnace—RHOX flowsheet with regenerative heat

exchanger (I.D. induced draft) (RHOX, 1989).