Page 150 - Wastewater Solids Incineration Systems

P. 150

Heat Recovery and Reuse 117

of auxiliary fuel, heat recovery through recuperation was attempted. Fuel savings

were 35 to 75% at 540°C (1000°F) air preheat and combustion could be self-sustaining

at 650°C (1200°F) and a well-dewatered feed cake (25 to 27% solids). Recuperation is

the most basic and cost-effective form of heat recovery.

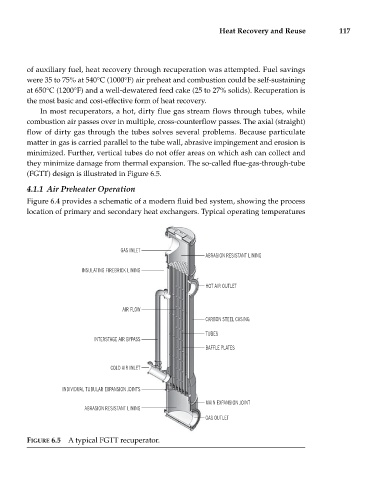

In most recuperators, a hot, dirty flue gas stream flows through tubes, while

combustion air passes over in multiple, cross-counterflow passes. The axial (straight)

flow of dirty gas through the tubes solves several problems. Because particulate

matter in gas is carried parallel to the tube wall, abrasive impingement and erosion is

minimized. Further, vertical tubes do not offer areas on which ash can collect and

they minimize damage from thermal expansion. The so-called flue-gas-through-tube

(FGTT) design is illustrated in Figure 6.5.

4.1.1 Air Preheater Operation

Figure 6.4 provides a schematic of a modern fluid bed system, showing the process

location of primary and secondary heat exchangers. Typical operating temperatures

GAS INLET

ABRASION RESISTANT LINING

INSULATING FIREBRICK LINING

HOT AIR OUTLET

AIR FLOW

CARBON STEEL CASING

TUBES

INTERSTAGE AIR BYPASS

BAFFLE PLATES

COLD AIR INLET

INDIVIDUAL TUBULAR EXPANSION JOINTS

MAIN EXPANSION JOINT

ABRASION RESISTANT LINING

GAS OUTLET

FIGURE 6.5 A typical FGTT recuperator.