Page 180 - Wastewater Solids Incineration Systems

P. 180

Emission Control and Monitoring 147

zero hearth afterburner. In some cases, refractory baffles are constructed on the top

hearth to ensure adequate residence time.

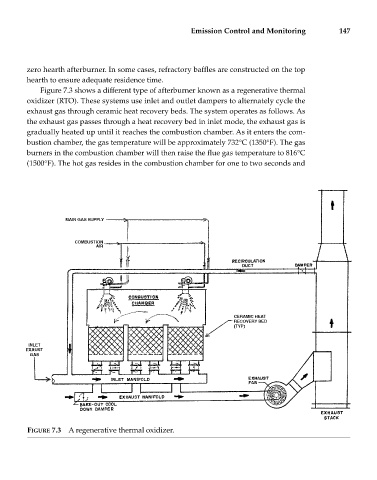

Figure 7.3 shows a different type of afterburner known as a regenerative thermal

oxidizer (RTO). These systems use inlet and outlet dampers to alternately cycle the

exhaust gas through ceramic heat recovery beds. The system operates as follows. As

the exhaust gas passes through a heat recovery bed in inlet mode, the exhaust gas is

gradually heated up until it reaches the combustion chamber. As it enters the com-

bustion chamber, the gas temperature will be approximately 732°C (1350°F). The gas

burners in the combustion chamber will then raise the flue gas temperature to 816°C

(1500°F). The hot gas resides in the combustion chamber for one to two seconds and

FIGURE 7.3 A regenerative thermal oxidizer.