Page 182 - Wastewater Solids Incineration Systems

P. 182

Emission Control and Monitoring 149

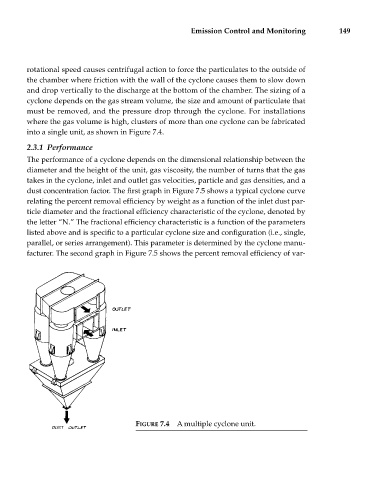

rotational speed causes centrifugal action to force the particulates to the outside of

the chamber where friction with the wall of the cyclone causes them to slow down

and drop vertically to the discharge at the bottom of the chamber. The sizing of a

cyclone depends on the gas stream volume, the size and amount of particulate that

must be removed, and the pressure drop through the cyclone. For installations

where the gas volume is high, clusters of more than one cyclone can be fabricated

into a single unit, as shown in Figure 7.4.

2.3.1 Performance

The performance of a cyclone depends on the dimensional relationship between the

diameter and the height of the unit, gas viscosity, the number of turns that the gas

takes in the cyclone, inlet and outlet gas velocities, particle and gas densities, and a

dust concentration factor. The first graph in Figure 7.5 shows a typical cyclone curve

relating the percent removal efficiency by weight as a function of the inlet dust par-

ticle diameter and the fractional efficiency characteristic of the cyclone, denoted by

the letter “N.” The fractional efficiency characteristic is a function of the parameters

listed above and is specific to a particular cyclone size and configuration (i.e., single,

parallel, or series arrangement). This parameter is determined by the cyclone manu-

facturer. The second graph in Figure 7.5 shows the percent removal efficiency of var-

FIGURE 7.4 A multiple cyclone unit.