Page 306 - Wastewater Solids Incineration Systems

P. 306

Incinerator Maintenance 267

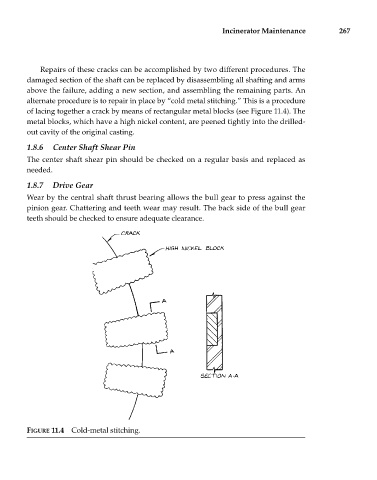

Repairs of these cracks can be accomplished by two different procedures. The

damaged section of the shaft can be replaced by disassembling all shafting and arms

above the failure, adding a new section, and assembling the remaining parts. An

alternate procedure is to repair in place by “cold metal stitching.” This is a procedure

of lacing together a crack by means of rectangular metal blocks (see Figure 11.4). The

metal blocks, which have a high nickel content, are peened tightly into the drilled-

out cavity of the original casting.

1.8.6 Center Shaft Shear Pin

The center shaft shear pin should be checked on a regular basis and replaced as

needed.

1.8.7 Drive Gear

Wear by the central shaft thrust bearing allows the bull gear to press against the

pinion gear. Chattering and teeth wear may result. The back side of the bull gear

teeth should be checked to ensure adequate clearance.

FIGURE 11.4 Cold-metal stitching.