Page 95 - Wastewater Solids Incineration Systems

P. 95

64 Wastewater Solids Incineration Systems

Compressed Air

Exhaust

Gas Duct Continuous Emissions

High-Pressure Sand Service Water Monitoring System

Water Pump Storage

Stack

Sand

Caustic

Sludge Heat Exchangers

Feed PrimarySecondary

Purge Blower

Sludge

Dewatering Service Water

Feed Pump Circulating

Pump

Purge Air Blower Fluidizing

Air Blower Venturi Tray Caustic

Auxiliary Scrubber Scrubber Wet

Fuel Preheat Burner

Oil Combustion Air Reheat Air ESP

Preheat Preheat Blower Ash Treatment

Settling Lagoon

Gas

Feed

Auxiliary

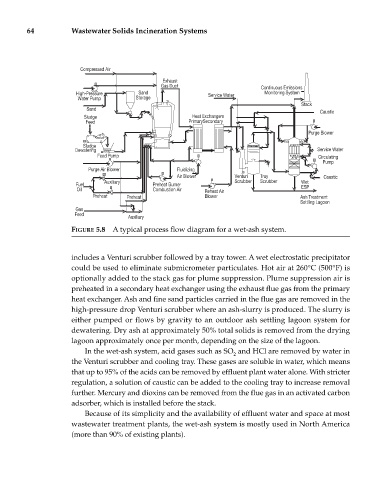

FIGURE 5.8 A typical process flow diagram for a wet-ash system.

includes a Venturi scrubber followed by a tray tower. A wet electrostatic precipitator

could be used to eliminate submicrometer particulates. Hot air at 260°C (500°F) is

optionally added to the stack gas for plume suppression. Plume suppression air is

preheated in a secondary heat exchanger using the exhaust flue gas from the primary

heat exchanger. Ash and fine sand particles carried in the flue gas are removed in the

high-pressure drop Venturi scrubber where an ash-slurry is produced. The slurry is

either pumped or flows by gravity to an outdoor ash settling lagoon system for

dewatering. Dry ash at approximately 50% total solids is removed from the drying

lagoon approximately once per month, depending on the size of the lagoon.

In the wet-ash system, acid gases such as SO and HCl are removed by water in

2

the Venturi scrubber and cooling tray. These gases are soluble in water, which means

that up to 95% of the acids can be removed by effluent plant water alone. With stricter

regulation, a solution of caustic can be added to the cooling tray to increase removal

further. Mercury and dioxins can be removed from the flue gas in an activated carbon

adsorber, which is installed before the stack.

Because of its simplicity and the availability of effluent water and space at most

wastewater treatment plants, the wet-ash system is mostly used in North America

(more than 90% of existing plants).