Page 96 - Wastewater Solids Incineration Systems

P. 96

Combustion Technology 65

Sand Silo Flue Gas Expansion

Tank Chemical

Silo

Stack

Incinerator Fin Fan

Cooler

Heat

Exchanger Building Usage

Economizer

Sludge

ID Fan

Bag

Filter

Hot

Air for Water

Fluidization Circuit

Natural Gas Ash Silo

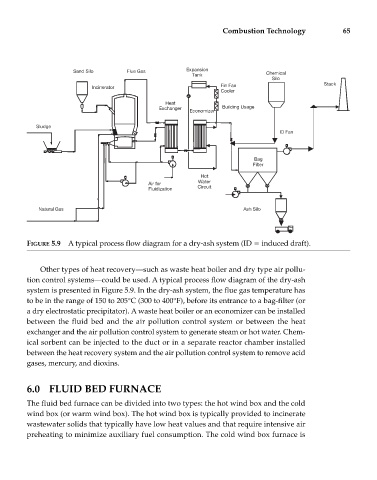

FIGURE 5.9 A typical process flow diagram for a dry-ash system (ID induced draft).

Other types of heat recovery—such as waste heat boiler and dry type air pollu-

tion control systems—could be used. A typical process flow diagram of the dry-ash

system is presented in Figure 5.9. In the dry-ash system, the flue gas temperature has

to be in the range of 150 to 205°C (300 to 400°F), before its entrance to a bag-filter (or

a dry electrostatic precipitator). A waste heat boiler or an economizer can be installed

between the fluid bed and the air pollution control system or between the heat

exchanger and the air pollution control system to generate steam or hot water. Chem-

ical sorbent can be injected to the duct or in a separate reactor chamber installed

between the heat recovery system and the air pollution control system to remove acid

gases, mercury, and dioxins.

6.0 FLUID BED FURNACE

The fluid bed furnace can be divided into two types: the hot wind box and the cold

wind box (or warm wind box). The hot wind box is typically provided to incinerate

wastewater solids that typically have low heat values and that require intensive air

preheating to minimize auxiliary fuel consumption. The cold wind box furnace is