Page 143 - Water Engineering Hydraulics, Distribution and Treatment

P. 143

121

5.2 Fluid Transport

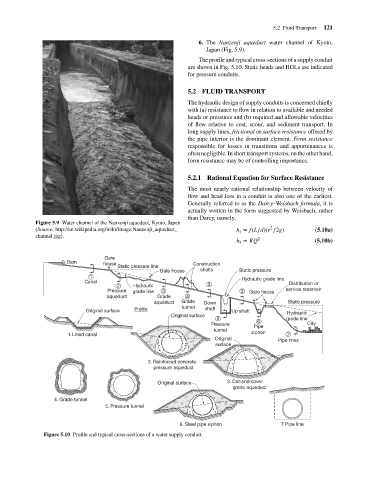

6. The Nanzenji aqueduct water channel of Kyoto,

Japan (Fig. 5.9).

The profile and typical cross-sections of a supply conduit

are shown in Fig. 5.10. Static heads and HGLs are indicated

for pressure conduits.

5.2 FLUID TRANSPORT

The hydraulic design of supply conduits is concerned chiefly

with (a) resistance to flow in relation to available and needed

heads or pressures and (b) required and allowable velocities

of flow relative to cost, scour, and sediment transport. In

long supply lines, frictional or surface resistance offered by

the pipe interior is the dominant element. Form resistance

responsible for losses in transitions and appurtenances is

often negligible. In short transport systems, on the other hand,

form resistance may be of controlling importance.

5.2.1 Rational Equation for Surface Resistance

The most nearly rational relationship between velocity of

flow and head loss in a conduit is also one of the earliest.

Generally referred to as the Darcy–Weisbach formula,itis

actually written in the form suggested by Weisbach, rather

than Darcy, namely,

Figure 5.9 Water channel of the Nanzenji aqueduct, Kyoto, Japan

2

(Source: http://en.wikipedia.org/wiki/Image:Nanzenji_aqueduct_ h = f(L∕d)(v ∕2g) (5.10a)

f

channel.jpg). 2

h = KQ (5.10b)

f

Gate

Dam house Construction

Static pressure line

Gate house shafts Static pressure

1 Hydraulic grade line

Canal Distribution or

2 Hydraulic 3

Pressure grade line 3 3 Gate house service reservoir

aqueduct Grade 4

aqueduct Grade Down Static pressure

Original surface Profile tunnel shaft Up shaft Hydraulic

Original surface

5 grade line

6

Pressure Pipe City

tunnel siphon

1. Lined canal 7

Original Pipe lines

surface

2. Reinforced concrete

pressure aqueduct

Original surface 3. Cut-and-cover

grade aqueduct

4. Grade tunnel

5. Pressure tunnel

6. Steel pipe siphon 7. Pipe line

Figure 5.10 Profile and typical cross-sections of a water supply conduit.