Page 292 - Water Engineering Hydraulics, Distribution and Treatment

P. 292

270

Cross-Connection Control

Chapter 9

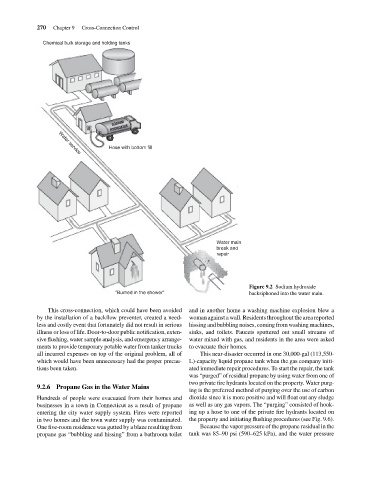

Chemical bulk storage and holding tanks

SODIUM

HYDROXIDE

Hose with bottom fill

Water service

Water main

break and

repair

Figure 9.2 Sodium hydroxide

“Burned in the shower” backsiphoned into the water main.

This cross-connection, which could have been avoided and in another home a washing machine explosion blew a

by the installation of a backflow preventer, created a need- woman against a wall. Residents throughout the area reported

less and costly event that fortunately did not result in serious hissing and bubbling noises, coming from washing machines,

illness or loss of life. Door-to-door public notification, exten- sinks, and toilets. Faucets sputtered out small streams of

sive flushing, water sample analysis, and emergency arrange- water mixed with gas, and residents in the area were asked

ments to provide temporary potable water from tanker trucks to evacuate their homes.

all incurred expenses on top of the original problem, all of This near-disaster occurred in one 30,000-gal (113,550-

which would have been unnecessary had the proper precau- L)-capacity liquid propane tank when the gas company initi-

tions been taken. ated immediate repair procedures. To start the repair, the tank

was “purged” of residual propane by using water from one of

two private fire hydrants located on the property. Water purg-

9.2.6 Propane Gas in the Water Mains

ing is the preferred method of purging over the use of carbon

Hundreds of people were evacuated from their homes and dioxide since it is more positive and will float out any sludge

businesses in a town in Connecticut as a result of propane as well as any gas vapors. The “purging” consisted of hook-

entering the city water supply system. Fires were reported ing up a hose to one of the private fire hydrants located on

in two homes and the town water supply was contaminated. the property and initiating flushing procedures (see Fig. 9.6).

One five-room residence was gutted by a blaze resulting from Because the vapor pressure of the propane residual in the

propane gas “bubbling and hissing” from a bathroom toilet tank was 85–90 psi (590–625 kPa), and the water pressure