Page 294 - Water Engineering Hydraulics, Distribution and Treatment

P. 294

272

Cross-Connection Control

Chapter 9

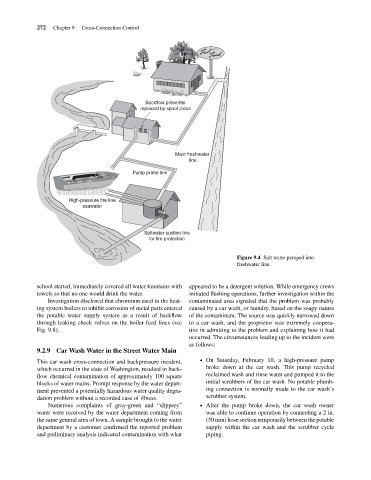

Backflow preventer

replaced by spool piece

Main freshwater

line

Pump prime line

High-pressure fire line

seawater

Saltwater suction line

for fire protection

Figure 9.4 Salt water pumped into

freshwater line.

school started, immediately covered all water fountains with appeared to be a detergent solution. While emergency crews

towels so that no one would drink the water. initiated flushing operations, further investigation within the

Investigation disclosed that chromium used in the heat- contaminated area signaled that the problem was probably

ing system boilers to inhibit corrosion of metal parts entered caused by a car wash, or laundry, based on the soapy nature

the potable water supply system as a result of backflow of the contaminant. The source was quickly narrowed down

through leaking check valves on the boiler feed lines (see to a car wash, and the proprietor was extremely coopera-

Fig. 9.8). tive in admitting to the problem and explaining how it had

occurred. The circumstances leading up to the incident were

as follows:

9.2.9 Car Wash Water in the Street Water Main

This car wash cross-connection and backpressure incident, On Saturday, February 10, a high-pressure pump

which occurred in the state of Washington, resulted in back- broke down at the car wash. This pump recycled

flow chemical contamination of approximately 100 square reclaimed wash and rinse water and pumped it to the

blocks of water mains. Prompt response by the water depart- initial scrubbers of the car wash. No potable plumb-

ment prevented a potentially hazardous water quality degra- ing connection is normally made to the car wash’s

dation problem without a recorded case of illness. scrubber system.

Numerous complaints of gray-green and “slippery” After the pump broke down, the car wash owner

water were received by the water department coming from was able to continue operation by connecting a 2 in.

the same general area of town. A sample brought to the water (50 mm) hose section temporarily between the potable

department by a customer confirmed the reported problem supply within the car wash and the scrubber cycle

and preliminary analysis indicated contamination with what piping.