Page 109 - Welding Robots Technology, System Issues, and Applications

P. 109

50 mm 100 mm Sensors for Welding Robots 95

Trajectory of 1 mm 3 mm

the weld joint

80

Weld voltage

70

variance

60

50

40

30

0 20 40 60 80 100 120

100

80 Decision function

60

Threshold and alarm

40 level

20

0

0 20 40 60 80 100 120

Position (mm)

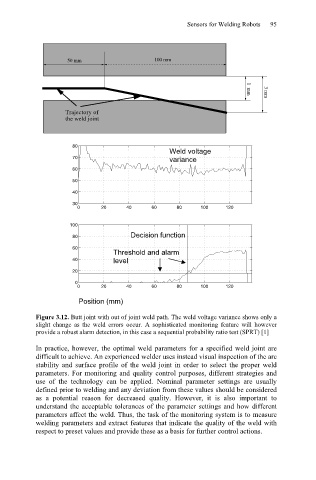

Figure 3.12. Butt joint with out of joint weld path. The weld voltage variance shows only a

slight change as the weld errors occur. A sophisticated monitoring feature will however

provide a robust alarm detection, in this case a sequential probability ratio test (SPRT) [1]

In practice, however, the optimal weld parameters for a specified weld joint are

difficult to achieve. An experienced welder uses instead visual inspection of the arc

stability and surface profile of the weld joint in order to select the proper weld

parameters. For monitoring and quality control purposes, different strategies and

use of the technology can be applied. Nominal parameter settings are usually

defined prior to welding and any deviation from these values should be considered

as a potential reason for decreased quality. However, it is also important to

understand the acceptable tolerances of the parameter settings and how different

parameters affect the weld. Thus, the task of the monitoring system is to measure

welding parameters and extract features that indicate the quality of the weld with

respect to preset values and provide these as a basis for further control actions.