Page 114 - Welding Robots Technology, System Issues, and Applications

P. 114

100 Welding Robots

x

x A minimum mass transferred per short-circuit

A minimum spatter loss

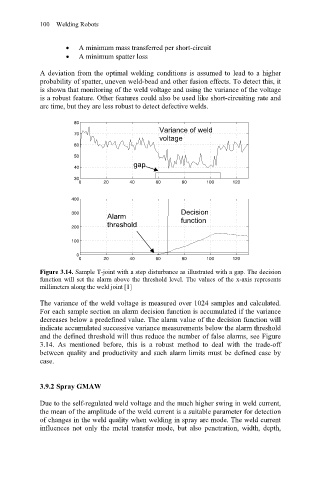

A deviation from the optimal welding conditions is assumed to lead to a higher

probability of spatter, uneven weld-bead and other fusion effects. To detect this, it

is shown that monitoring of the weld voltage and using the variance of the voltage

is a robust feature. Other features could also be used like short-circuiting rate and

arc time, but they are less robust to detect defective welds.

80

Variance of weld

70

voltage

60

50

gap

40

30

0 20 40 60 80 100 120

400

300 Decision

Alarm function

threshold

200

100

0

0 20 40 60 80 100 120

Figure 3.14. Sample T-joint with a step disturbance as illustrated with a gap. The decision

function will set the alarm above the threshold level. The values of the x-axis represents

millimeters along the weld joint [1]

The variance of the weld voltage is measured over 1024 samples and calculated.

For each sample section an alarm decision function is accumulated if the variance

decreases below a predefined value. The alarm value of the decision function will

indicate accumulated successive variance measurements below the alarm threshold

and the defined threshold will thus reduce the number of false alarms, see Figure

3.14. As mentioned before, this is a robust method to deal with the trade-off

between quality and productivity and such alarm limits must be defined case by

case.

3.9.2 Spray GMAW

Due to the self-regulated weld voltage and the much higher swing in weld current,

the mean of the amplitude of the weld current is a suitable parameter for detection

of changes in the weld quality when welding in spray arc mode. The weld current

influences not only the metal transfer mode, but also penetration, width, depth,