Page 87 - Well Control for Completions and Interventions

P. 87

78 Well Control for Completions and Interventions

• On the tubing side, integrity is provided by closure of the Christmas

tree valves. An additional barrier can be provided in the form of a

SC-SSSV.

Installing a packer in the well brings with it additional complications.

• Annulus pressure build-up (APB) caused by fluid expansion must be

anticipated and controlled by regular monitoring and bleed off.

Failure to do so could result in tubing collapse or casing burst.

• The annulus usually becomes an integral part of the well integrity

envelope (the secondary barrier), and therefore annulus integrity must

be monitored and maintained. Loss of integrity will almost certainly

require a well intervention.

• With a packer in place, a circulation path is no longer available.

Circulation, for well kill or any other purpose, can only take place if a

circulation path is created. This must be close to the packer (for maxi-

mum effect). Some completions will include a circulation device, such

as a sliding sleeve or side pocket mandrel. In the absence of circulation

equipment, the only method of creating a circulation path is to perfo-

rate (punch) the production tubing above the packer.

• Workover (re-completion) becomes more complex. If the tubing is

connected (anchored) to the packer it must be released before it can

be recovered. If a dynamic (moving) seal assembly is stabbed into the

packer, then the completion below the packer remains in place unless

the packer is recovered separately. Packer replacement can be prob-

lematic, if permanent packers have to be removed.

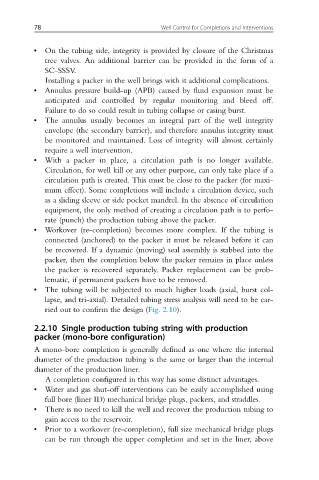

• The tubing will be subjected to much higher loads (axial, burst col-

lapse, and tri-axial). Detailed tubing stress analysis will need to be car-

ried out to confirm the design (Fig. 2.10).

2.2.10 Single production tubing string with production

packer (mono-bore configuration)

A mono-bore completion is generally defined as one where the internal

diameter of the production tubing is the same or larger than the internal

diameter of the production liner.

A completion configured in this way has some distinct advantages.

• Water and gas shut-off interventions can be easily accomplished using

full bore (liner ID) mechanical bridge plugs, packers, and straddles.

• There is no need to kill the well and recover the production tubing to

gain access to the reservoir.

• Prior to a workover (re-completion), full size mechanical bridge plugs

can be run through the upper completion and set in the liner, above