Page 369 - Wind Energy Handbook

P. 369

NUMBER OF BLADES 343

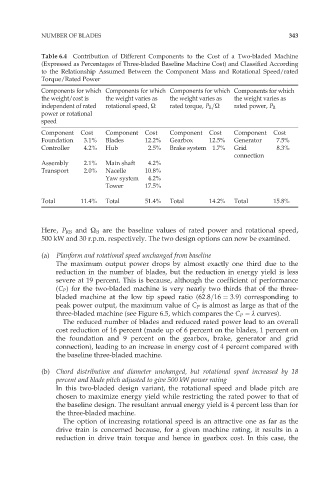

Table 6.4 Contribution of Different Components to the Cost of a Two-bladed Machine

(Expressed as Percentages of Three-bladed Baseline Machine Cost) and Classified According

to the Relationship Assumed Between the Component Mass and Rotational Speed/rated

Torque/Rated Power

Components for which Components for which Components for which Components for which

the weight/cost is the weight varies as the weight varies as the weight varies as

independent of rated rotational speed, Ù rated torque, P R =Ù rated power, P R

power or rotational

speed

Component Cost Component Cost Component Cost Component Cost

Foundation 3.1% Blades 12.2% Gearbox 12.5% Generator 7.5%

Controller 4.2% Hub 2.5% Brake system 1.7% Grid 8.3%

connection

Assembly 2.1% Main shaft 4.2%

Transport 2.0% Nacelle 10.8%

Yaw system 4.2%

Tower 17.5%

Total 11.4% Total 51.4% Total 14.2% Total 15.8%

Here, P RB and Ù B are the baseline values of rated power and rotational speed,

500 kW and 30 r.p.m. respectively. The two design options can now be examined.

(a) Planform and rotational speed unchanged from baseline

The maximum output power drops by almost exactly one third due to the

reduction in the number of blades, but the reduction in energy yield is less

severe at 19 percent. This is because, although the coefficient of performance

(C P ) for the two-bladed machine is very nearly two thirds that of the three-

bladed machine at the low tip speed ratio (62:8=16 ¼ 3:9) corresponding to

peak power output, the maximum value of C P is almost as large as that of the

three-bladed machine (see Figure 6.5, which compares the C P º curves).

The reduced number of blades and reduced rated power lead to an overall

cost reduction of 16 percent (made up of 6 percent on the blades, 1 percent on

the foundation and 9 percent on the gearbox, brake, generator and grid

connection), leading to an increase in energy cost of 4 percent compared with

the baseline three-bladed machine.

(b) Chord distribution and diameter unchanged, but rotational speed increased by 18

percent and blade pitch adjusted to give 500 kW power rating

In this two-bladed design variant, the rotational speed and blade pitch are

chosen to maximize energy yield while restricting the rated power to that of

the baseline design. The resultant annual energy yield is 4 percent less than for

the three-bladed machine.

The option of increasing rotational speed is an attractive one as far as the

drive train is concerned because, for a given machine rating, it results in a

reduction in drive train torque and hence in gearbox cost. In this case, the