Page 372 - Wind Energy Handbook

P. 372

346 CONCEPTUAL DESIGN OF HORIZONTAL-AXIS TURBINES

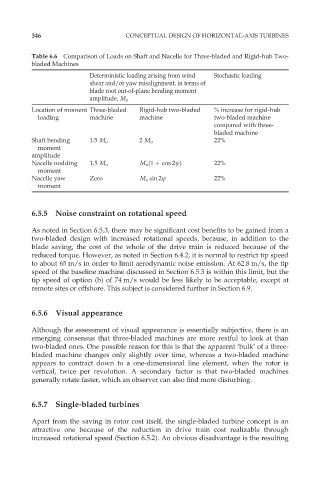

Table 6.6 Comparison of Loads on Shaft and Nacelle for Three-bladed and Rigid-hub Two-

bladed Machines

Deterministic loading arising from wind Stochastic loading

shear and/or yaw misalignment, in terms of

blade root out-of-plane bending moment

amplitude, M o

Location of moment Three-bladed Rigid-hub two-bladed % increase for rigid-hub

loading machine machine two-bladed machine

compared with three-

bladed machine

Shaft bending 1.5 M o 2 M o 22%

moment

amplitude

Nacelle nodding 1.5 M o M o (1 þ cos 2ł) 22%

moment

Nacelle yaw Zero M o sin 2ł 22%

moment

6.5.5 Noise constraint on rotational speed

As noted in Section 6.5.3, there may be significant cost benefits to be gained from a

two-bladed design with increased rotational speeds, because, in addition to the

blade saving, the cost of the whole of the drive train is reduced because of the

reduced torque. However, as noted in Section 6.4.2, it is normal to restrict tip speed

to about 65 m/s in order to limit aerodynamic noise emission. At 62.8 m/s, the tip

speed of the baseline machine discussed in Section 6.5.3 is within this limit, but the

tip speed of option (b) of 74 m/s would be less likely to be acceptable, except at

remote sites or offshore. This subject is considered further in Section 6.9.

6.5.6 Visual appearance

Although the assessment of visual appearance is essentially subjective, there is an

emerging consensus that three-bladed machines are more restful to look at than

two-bladed ones. One possible reason for this is that the apparent ‘bulk’ of a three-

bladed machine changes only slightly over time, whereas a two-bladed machine

appears to contract down to a one-dimensional line element, when the rotor is

vertical, twice per revolution. A secondary factor is that two-bladed machines

generally rotate faster, which an observer can also find more disturbing.

6.5.7 Single-bladed turbines

Apart from the saving in rotor cost itself, the single-bladed turbine concept is an

attractive one because of the reduction in drive train cost realizable through

increased rotational speed (Section 6.5.2). An obvious disadvantage is the resulting