Page 158 - Mechanical Behavior of Materials

P. 158

Section 4.7 Hardness Tests 159

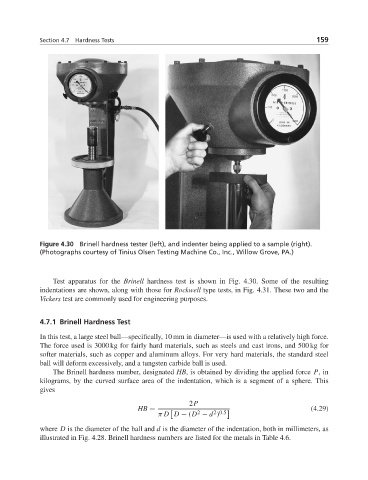

Figure 4.30 Brinell hardness tester (left), and indenter being applied to a sample (right).

(Photographs courtesy of Tinius Olsen Testing Machine Co., Inc., Willow Grove, PA.)

Test apparatus for the Brinell hardness test is shown in Fig. 4.30. Some of the resulting

indentations are shown, along with those for Rockwell type tests, in Fig. 4.31. These two and the

Vickers test are commonly used for engineering purposes.

4.7.1 Brinell Hardness Test

In this test, a large steel ball—specifically, 10 mm in diameter—is used with a relatively high force.

The force used is 3000 kg for fairly hard materials, such as steels and cast irons, and 500 kg for

softer materials, such as copper and aluminum alloys. For very hard materials, the standard steel

ball will deform excessively, and a tungsten carbide ball is used.

The Brinell hardness number, designated HB, is obtained by dividing the applied force P,in

kilograms, by the curved surface area of the indentation, which is a segment of a sphere. This

gives

2P

HB =

(4.29)

2

2 0.5

π D D − (D − d )

where D is the diameter of the ball and d is the diameter of the indentation, both in millimeters, as

illustrated in Fig. 4.28. Brinell hardness numbers are listed for the metals in Table 4.6.