Page 155 - Mechanical Behavior of Materials

P. 155

156 Chapter 4 Mechanical Testing: Tension Test and Other Basic Tests

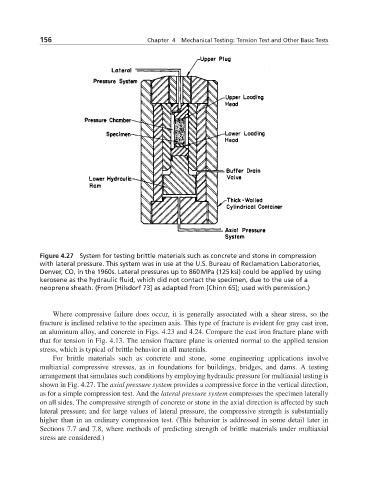

Figure 4.27 System for testing brittle materials such as concrete and stone in compression

with lateral pressure. This system was in use at the U.S. Bureau of Reclamation Laboratories,

Denver, CO, in the 1960s. Lateral pressures up to 860 MPa (125 ksi) could be applied by using

kerosene as the hydraulic fluid, which did not contact the specimen, due to the use of a

neoprene sheath. (From [Hilsdorf 73] as adapted from [Chinn 65]; used with permission.)

Where compressive failure does occur, it is generally associated with a shear stress, so the

fracture is inclined relative to the specimen axis. This type of fracture is evident for gray cast iron,

an aluminum alloy, and concrete in Figs. 4.23 and 4.24. Compare the cast iron fracture plane with

that for tension in Fig. 4.13. The tension fracture plane is oriented normal to the applied tension

stress, which is typical of brittle behavior in all materials.

For brittle materials such as concrete and stone, some engineering applications involve

multiaxial compressive stresses, as in foundations for buildings, bridges, and dams. A testing

arrangement that simulates such conditions by employing hydraulic pressure for multiaxial testing is

shown in Fig. 4.27. The axial pressure system provides a compressive force in the vertical direction,

as for a simple compression test. And the lateral pressure system compresses the specimen laterally

on all sides. The compressive strength of concrete or stone in the axial direction is affected by such

lateral pressure; and for large values of lateral pressure, the compressive strength is substantially

higher than in an ordinary compression test. (This behavior is addressed in some detail later in

Sections 7.7 and 7.8, where methods of predicting strength of brittle materials under multiaxial

stress are considered.)