Page 152 - Mechanical Behavior of Materials

P. 152

Section 4.6 Compression Test 153

Figure 4.22 Compression test in a universal testing machine that uses a spherical-seated

bearing block. (From [ASTM 97] Std. E9; copyright c ASTM; reprinted with permission.)

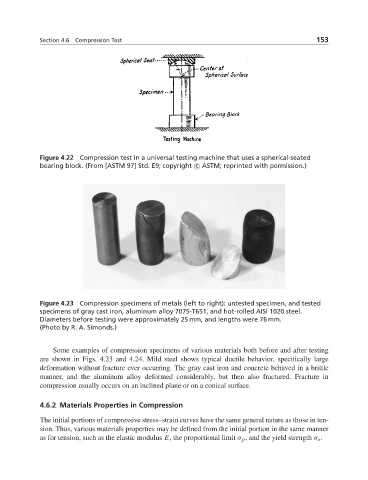

Figure 4.23 Compression specimens of metals (left to right): untested specimen, and tested

specimens of gray cast iron, aluminum alloy 7075-T651, and hot-rolled AISI 1020 steel.

Diameters before testing were approximately 25 mm, and lengths were 76 mm.

(Photo by R. A. Simonds.)

Some examples of compression specimens of various materials both before and after testing

are shown in Figs. 4.23 and 4.24. Mild steel shows typical ductile behavior, specifically large

deformation without fracture ever occurring. The gray cast iron and concrete behaved in a brittle

manner, and the aluminum alloy deformed considerably, but then also fractured. Fracture in

compression usually occurs on an inclined plane or on a conical surface.

4.6.2 Materials Properties in Compression

The initial portions of compressive stress–strain curves have the same general nature as those in ten-

sion. Thus, various materials properties may be defined from the initial portion in the same manner

as for tension, such as the elastic modulus E, the proportional limit σ p , and the yield strength σ o .