Page 85 - Mechanical Behavior of Materials

P. 85

86 Chapter 3 A Survey of Engineering Materials

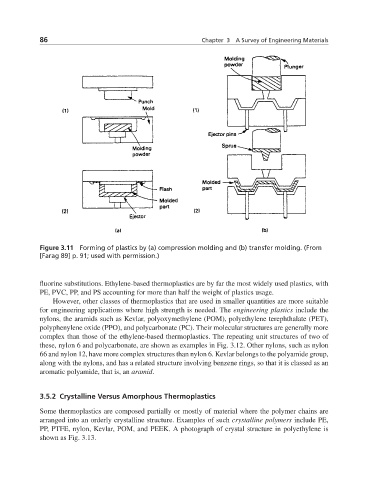

Figure 3.11 Forming of plastics by (a) compression molding and (b) transfer molding. (From

[Farag 89] p. 91; used with permission.)

fluorine substitutions. Ethylene-based thermoplastics are by far the most widely used plastics, with

PE, PVC, PP, and PS accounting for more than half the weight of plastics usage.

However, other classes of thermoplastics that are used in smaller quantities are more suitable

for engineering applications where high strength is needed. The engineering plastics include the

nylons, the aramids such as Kevlar, polyoxymethylene (POM), polyethylene terephthalate (PET),

polyphenylene oxide (PPO), and polycarbonate (PC). Their molecular structures are generally more

complex than those of the ethylene-based thermoplastics. The repeating unit structures of two of

these, nylon 6 and polycarbonate, are shown as examples in Fig. 3.12. Other nylons, such as nylon

66 and nylon 12, have more complex structures than nylon 6. Kevlar belongs to the polyamide group,

along with the nylons, and has a related structure involving benzene rings, so that it is classed as an

aromatic polyamide, that is, an aramid.

3.5.2 Crystalline Versus Amorphous Thermoplastics

Some thermoplastics are composed partially or mostly of material where the polymer chains are

arranged into an orderly crystalline structure. Examples of such crystalline polymers include PE,

PP, PTFE, nylon, Kevlar, POM, and PEEK. A photograph of crystal structure in polyethylene is

shown as Fig. 3.13.