Page 150 - Introduction to Marine Engineering

P. 150

136 Auxiliaries

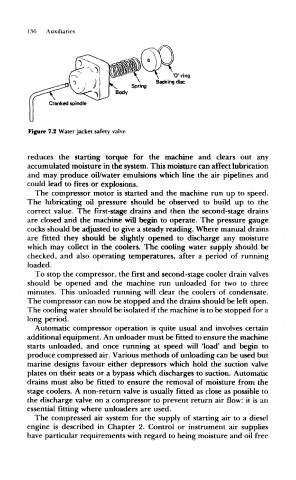

'Q'-ring

Backing disc

Figure 7.2 Water jacket safety valve

reduces the starting torque for the machine and clears out any

accumulated moisture in the system. This moisture can affect lubrication

and may produce oil/water emulsions which line the air pipelines and

could lead to fires or explosions.

The compressor motor is started and the machine run up to speed.

The lubricating oil pressure should be observed to build up to the

correct value. The first-stage drains and then the second-stage drains

are closed and the machine will begin to operate. The pressure gauge

cocks should be adjusted to give a steady reading. Where manual drains

are fitted they should be slightly opened to discharge any moisture

which may collect in the coolers. The cooling water supply should be

checked, and also operating temperatures, after a period of running

loaded.

To stop the compressor, the first and second-stage cooler drain valves

should be opened and the machine run unloaded for two to three

minutes. This unloaded running will clear the coolers of condensate.

The compressor can now be stopped and the drains should be left open.

The cooling water should be isolated if the machine is to be stopped for a

long period.

Automatic compressor operation is quite usual and involves certain

additional equipment. An unloader must be fitted to ensure the machine

starts unloaded, and once running at speed will load' and begin to

produce compressed air. Various methods of unloading can be used but

marine designs favour either depressors which hold the suction valve

plates on their seats or a bypass which discharges to suction. Automatic

drains must also be fitted to ensure the removal of moisture from the

stage coolers. A non-return valve is usually fitted as close as possible to

the discharge valve on a compressor to prevent return air flow: it is an

essential fitting where unloaders are used.

The compressed air system for the supply of starting air to a diesel

engine is described in Chapter 2. Control or instrument air supplies

have particular requirements with regard to being moisture and oil free