Page 152 - Introduction to Marine Engineering

P. 152

138 Auxiliaries

Heat exchangers

Heat exchangers on board ship are mainly coolers where a hot liquid is

cooled by sea water. There are some instances where liquid heating is

required, such as heavy fuel oil heaters and sea water heaters for tank

cleaning. Although being heat exchangers, the main condenser for a

steam ship and the evaporator/distiller are dealt with separately (see

Chapter 5).

The heat exchange process is accomplished by having the two liquids

pass on either side of a conducting surface. The heat from the hot liquid

passes to the cold liquid and the conducting surface, i.e. the tube wall, is

at a temperature between the two. It is usual for marine heat exchangers

to have the two liquids flowing in opposite directions, i.e. counter or

contra flow. This arrangement provides a fairly constant temperature

difference between the two liquids and therefore the maximum heat

transfer for the available surface area.

Coolers

Coolers at sea fall into two groups, shell and tube and the plate type. Both

are considered below.

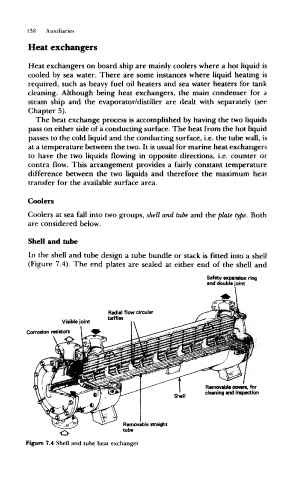

Shell and tube

In the shell and tube design a tube bundle or stack is fitted into a shell

(Figure 7.4). The end plates are sealed at either end of the shell and

Safety expansion ring

and double joint

Radial flow circular

baffles

Visible joint

Corrosion resistors

Removable covers, for

cleaning and inspection

Removable straight

tube

Figure 7.4 Shell and tube heat exchanger