Page 158 - Materials Chemistry, Second Edition

P. 158

142 3 Life Cycle Inventory Analysis

To date, according to DSD only transparent bottles are suited for material

recycling. 192) Coloured bottles can, however, be recovered as material if they

are transparent. The PA portion of multilayer bottles is generally no obstacle

for recycling.

The material recycling rate results from the following material flows: 80% of

the PET bottles are collected separately by DSD, 20% of the remaining bottles are

dumped in the litter bin of households (these are collected by the municipal waste

disposal system). An 80% of DSD collected bottles are distributed in the sorting

plants as follows: PET bottles 58%, mixed plastics 27% and other remainders 15%.

The PET bottle fraction is subject to re-sorting with a yield of 97%. This results

in a recycling rate (referred to the total quantity) of 45% (see Table 3.10 and

Figure 3.29).

3.7.1.3 Handling of Sorting Residues and Mixed Plastics Fraction

Sorting residues of by DSD collected beverage cartons and PET bottles in 2005

according to information provided by DSD to equal parts have been

• disposed as waste (MSWI) or

• used in cement plants.

Mixed plastics are recovered thermally (incineration with energy recovery) or as

raw material. The mix of recovery is as follows:

• Cement plant (70%),

• Secondary raw material recycling plant (gasification to methanol) (∼15%),

• In a blast furnace as fuel(∼15%).

The unit processes considered for recycling are presented in Section 3.7.2.

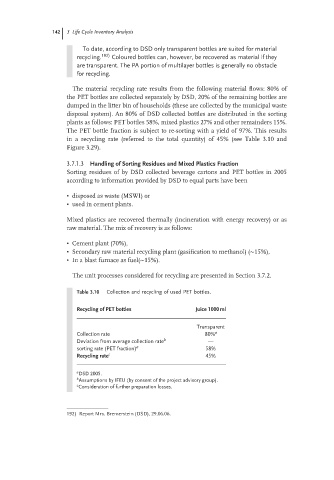

Table 3.10 Collection and recycling of used PET bottles.

Recycling of PET bottles Juice 1000 ml

Transparent

Collection rate 80% a

Deviation from average collection rate b —

sorting rate (PET fraction) a 58%

Recycling rate c 45%

a DSD 2005.

b

Assumptions by IFEU (by consent of the project advisory group).

c Consideration of further preparation losses.

192) Report Mrs. Bremerstein (DSD), 29.06.06.