Page 161 - Materials Chemistry, Second Edition

P. 161

3.7 Illustration of the Inventory Phase by an Example 145

Material/product Data basis

The data record covers production of HDPE granulates starting with the

extraction of raw materials from deposits including associated processes.

The data refer to a period around 1999. They were procured from a total of 24

polymerisation plants. The plants considered cover an annual production of

3 870 000 tons. The European total production in 1999 was approximately

4 310 000 tons. The data thus represent 89.7% of Western European HDPE

production PlasticsEurope (2005b)

PP production Polypropylene results from catalytic polymerisation of unsaturated propy-

lene to long chained polypropylene. The two most important procedures

are low pressure-, precipitation- and gas- phase-polymerisation. In a con-

cluding step the polymer powder is processed to granulates by extrusion

The data record covers production of PP granulate starting by the

extraction of raw materials from deposits including associated processes.

The data refer to a period around 1999. They were procured from a total of 28

polymerisation plants. The plants considered cover an annual production of

5 690 000 tons. The European total production in 1999 was approximately

7 400 000 tons. The data thus represent 76.9% of Western European PP

production PlasticsEurope (2005c)

PA (Nylon 66) Nylon is either produced by direct polymerisation of amino acids or by

production reaction of a diamine with a two proton acid. Nylon 66 is formed in the

reaction of hexamethylenediamine and adipic acid

The data record covers production of PA 66 starting with the extraction

of raw materials from deposits including associated processes. The data

refer to a period around 1996 PlasticsEurope (2005d). Information on plants

considered and the representativity of the data records is not available

PET Data on the primary production of PET are of special importance for this

production study. The PET data record used here was compiled on behalf of PETCORE

IFEU (2004) (PET of container recycling Europe) in the context of an LCA.

Data on the production of PET granulates are so far not yet published;

from the point of view of the authors greater transparency of this data

record is a strong argument for its use compared to the corresponding

data record of PlasticsEurope. (The specific environmental impact for the

eligibility of PET would be higher by use of the PlasticEurope data as with

application of the newer data record described here.)

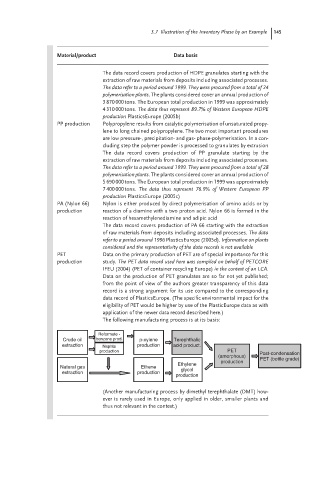

The following manufacturing process is at its basis:

Reformate -

Crude oil benzene prod. p-xylene Terephthalic

extraction Naphta production acid product.

production PET Post-condensation

(amorphous) PET (bottle grade)

production

Ethylene

Natural gas Ethene glycol

extraction production

production

(Another manufacturing process by dimethyl terephthalate (DMT) how-

ever is rarely used in Europe, only applied in older, smaller plants and

thus not relevant in the context.)