Page 159 - Materials Chemistry, Second Edition

P. 159

3.7 Illustration of the Inventory Phase by an Example 143

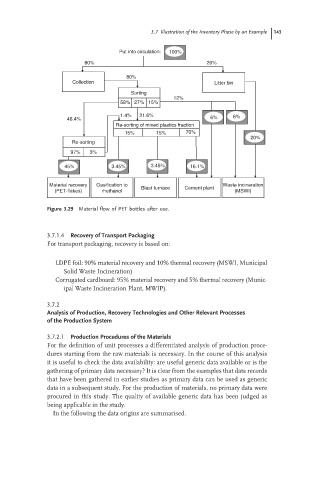

Put into circulation: 100%

80% 20%

80%

Collection Litter bin

Sorting

12%

58% 27% 15%

1.4% 21.6% 6%

46.4% 6%

Re-sorting of mixed plastics fraction

15% 15% 70%

20%

Re-sorting

97% 3%

45% 3.45% 3.45% 16.1%

Material recovery Gasification to Blast furnace Cement plant Waste incineration

(PET-flakes) methanol (MSWI)

Figure 3.29 Material flow of PET bottles after use.

3.7.1.4 Recovery of Transport Packaging

For transport packaging, recovery is based on:

LDPE foil: 90% material recovery and 10% thermal recovery (MSWI, Municipal

Solid Waste Incineration)

Corrugated cardboard: 95% material recovery and 5% thermal recovery (Munic-

ipal Waste Incineration Plant, MWIP).

3.7.2

Analysis of Production, Recovery Technologies and Other Relevant Processes

of the Production System

3.7.2.1 Production Procedures of the Materials

For the definition of unit processes a differentiated analysis of production proce-

dures starting from the raw materials is necessary. In the course of this analysis

it is useful to check the data availability: are useful generic data available or is the

gathering of primary data necessary? It is clear from the examples that data records

that have been gathered in earlier studies as primary data can be used as generic

data in a subsequent study. For the production of materials, no primary data were

procured in this study. The quality of available generic data has been judged as

being applicable in the study.

In the following the data origins are summarised.