Page 171 - Materials Chemistry, Second Edition

P. 171

3.7 Illustration of the Inventory Phase by an Example 155

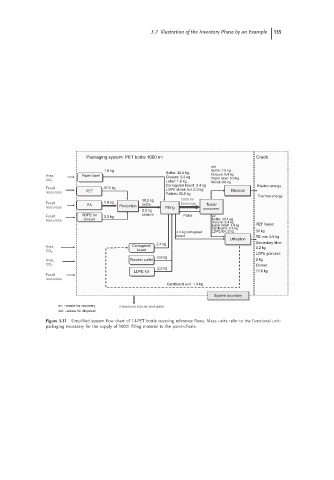

Packaging system: PET bottle 1000 ml Credit

wd:

1.8 kg Bottle: 38.0 kg, Bottle: 7.6 kg

Area, Paper label Closure: 3.3 kg Closure: 0.9 kg

CO 2 Label: 1.8 kg Paper label: 0.3 kg

Wood: 0.6 kg

Corrugated board: 2.4 kg Electric energy

Fossil 37.2 kg LDPE shrink foil: 2.3 kg Disposal

resources PET Pallets: 30.8 kg

Thermal energy

38.2 kg 1000 ml

Fossil PA 1.9 kg bottle beverage Trade/

resources Production Filling

3.3 kg consumer

Fossil HDPE for 3.3 kg closure Pallet wr:

resources closure bottle: 30.4 kg

closure: 2.4 kg

paper label: 1.4 kg PET flakes:

cardboard: 2.3 kg

4.4 kg corrugated LDPE foil: 2 kg 30 kg

board PE mix: 0.9 kg

Utilisation

Secondary fibre:

2.4 kg

Area, Corrugated 0.2 kg

board

CO 2

LDPE granules:

0.6 kg

Area, Wooden pallet 2 kg

CO 2 Clinker:

2.3 kg

LDPE-foil 71.6 kg

Fossil

resources

Cardboard (wr): 1.9 kg

System boundary

wr: –waste for recovery Emissions into air and water

wd: –waste for disposal

Figure 3.31 Simplified system flow chart of 1-l-PET bottle covering reference flows. Mass units refer to the functional unit:

packaging necessary for the supply of 1000 l filling material to the point-of-sale.