Page 95 - Materials Chemistry, Second Edition

P. 95

80 A. Bjørn et al.

Ecosphere

Technosphere

Background System boundaries Foreground

system system

Upstream

Downstream

Legend

Process Product or Elementary

waste flow flow

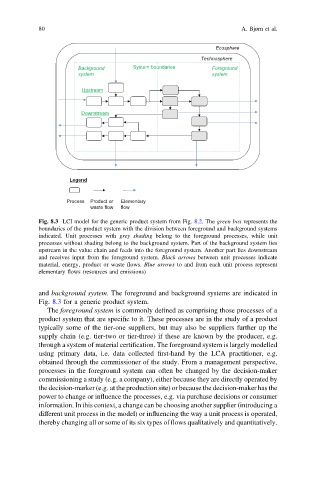

Fig. 8.3 LCI model for the generic product system from Fig. 8.2. The green box represents the

boundaries of the product system with the division between foreground and background systems

indicated. Unit processes with grey shading belong to the foreground processes, while unit

processes without shading belong to the background system. Part of the background system lies

upstream in the value chain and feeds into the foreground system. Another part lies downstream

and receives input from the foreground system. Black arrows between unit processes indicate

material, energy, product or waste flows. Blue arrows to and from each unit process represent

elementary flows (resources and emissions)

and background system. The foreground and background systems are indicated in

Fig. 8.3 for a generic product system.

The foreground system is commonly defined as comprising those processes of a

product system that are specific to it. These processes are in the study of a product

typically some of the tier-one suppliers, but may also be suppliers further up the

supply chain (e.g. tier-two or tier-three) if these are known by the producer, e.g.

through a system of material certification. The foreground system is largely modelled

using primary data, i.e. data collected first-hand by the LCA practitioner, e.g.

obtained through the commissioner of the study. From a management perspective,

processes in the foreground system can often be changed by the decision-maker

commissioning a study (e.g. a company), either because they are directly operated by

the decision-marker (e.g. at the production site) or because the decision-maker has the

power to change or influence the processes, e.g. via purchase decisions or consumer

information. In this context, a change can be choosing another supplier (introducing a

different unit process in the model) or influencing the way a unit process is operated,

thereby changing all or some of its six types of flows qualitatively and quantitatively.