Page 370 - Moving the Earth_ The Workbook of Excavation

P. 370

ROADWAYS

8.32 THE WORK

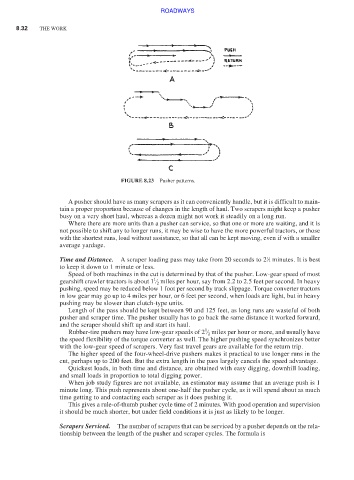

FIGURE 8.23 Pusher patterns.

A pusher should have as many scrapers as it can conveniently handle, but it is difficult to main-

tain a proper proportion because of changes in the length of haul. Two scrapers might keep a pusher

busy on a very short haul, whereas a dozen might not work it steadily on a long run.

Where there are more units than a pusher can service, so that one or more are waiting, and it is

not possible to shift any to longer runs, it may be wise to have the more powerful tractors, or those

with the shortest runs, load without assistance, so that all can be kept moving, even if with a smaller

average yardage.

Time and Distance. A scraper loading pass may take from 20 seconds to 2 ⁄2 minutes. It is best

1

to keep it down to 1 minute or less.

Speed of both machines in the cut is determined by that of the pusher. Low-gear speed of most

1

gearshift crawler tractors is about 1 ⁄ 2 miles per hour, say from 2.2 to 2.5 feet per second. In heavy

pushing, speed may be reduced below 1 foot per second by track slippage. Torque converter tractors

in low gear may go up to 4 miles per hour, or 6 feet per second, when loads are light, but in heavy

pushing may be slower than clutch-type units.

Length of the pass should be kept between 90 and 125 feet, as long runs are wasteful of both

pusher and scraper time. The pusher usually has to go back the same distance it worked forward,

and the scraper should shift up and start its haul.

1

Rubber-tire pushers may have low-gear speeds of 2 ⁄ 2 miles per hour or more, and usually have

the speed flexibility of the torque converter as well. The higher pushing speed synchronizes better

with the low-gear speed of scrapers. Very fast travel gears are available for the return trip.

The higher speed of the four-wheel-drive pushers makes it practical to use longer runs in the

cut, perhaps up to 200 feet. But the extra length in the pass largely cancels the speed advantage.

Quickest loads, in both time and distance, are obtained with easy digging, downhill loading,

and small loads in proportion to total digging power.

When job study figures are not available, an estimator may assume that an average push is 1

minute long. This push represents about one-half the pusher cycle, as it will spend about as much

time getting to and contacting each scraper as it does pushing it.

This gives a rule-of-thumb pusher cycle time of 2 minutes. With good operation and supervision

it should be much shorter, but under field conditions it is just as likely to be longer.

Scrapers Serviced. The number of scrapers that can be serviced by a pusher depends on the rela-

tionship between the length of the pusher and scraper cycles. The formula is