Page 371 - Moving the Earth_ The Workbook of Excavation

P. 371

ROADWAYS

ROADWAYS 8.33

scraper cycle

Scrapers per pusher

pusher cycle

If a scraper cycle were 5 minutes (300 seconds) and the pusher cycle 2 minutes (120 seconds),

1

the pusher could take care of 2 ⁄ 2 scrapers. This could be managed on a big job by using two pushers

and five scrapers, but on a small one the contractor would run either three or two.

Three scrapers would mean waiting time for scrapers; two of them would not keep the pusher

busy.

If pushing could be speeded up by more efficient patterns, better operating skills, or a faster

machine, so that the pusher cycle were reduced to 100 seconds, one pusher could take care of the

three scrapers.

The pusher cycle might be shortened to 90 seconds by keeping the scraper in the cut only 45

seconds and sending it out with a lighter load. Scraper cycle would be shortened by 15 seconds in

the cut and by about 10 seconds in the haul and dump, by faster acceleration and faster spreading.

On this basis one pusher could take care of three scrapers.

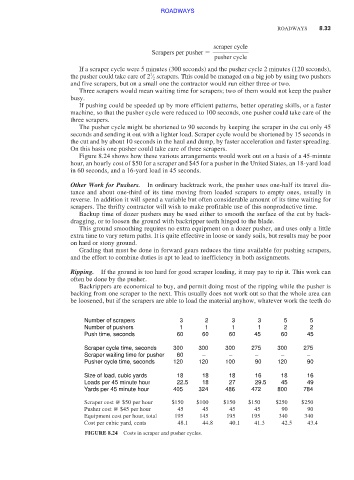

Figure 8.24 shows how these various arrangements would work out on a basis of a 45-minute

hour, an hourly cost of $50 for a scraper and $45 for a pusher in the United States, an 18-yard load

in 60 seconds, and a 16-yard load in 45 seconds.

Other Work for Pushers. In ordinary backtrack work, the pusher uses one-half its travel dis-

tance and about one-third of its time moving from loaded scrapers to empty ones, usually in

reverse. In addition it will spend a variable but often considerable amount of its time waiting for

scrapers. The thrifty contractor will wish to make profitable use of this nonproductive time.

Backup time of dozer pushers may be used either to smooth the surface of the cut by back-

dragging, or to loosen the ground with backripper teeth hinged to the blade.

This ground smoothing requires no extra equipment on a dozer pusher, and uses only a little

extra time to vary return paths. It is quite effective in loose or sandy soils, but results may be poor

on hard or stony ground.

Grading that must be done in forward gears reduces the time available for pushing scrapers,

and the effort to combine duties is apt to lead to inefficiency in both assignments.

Ripping. If the ground is too hard for good scraper loading, it may pay to rip it. This work can

often be done by the pusher.

Backrippers are economical to buy, and permit doing most of the ripping while the pusher is

backing from one scraper to the next. This usually does not work out so that the whole area can

be loosened, but if the scrapers are able to load the material anyhow, whatever work the teeth do

Number of scrapers 3 2 3 3 5 5

Number of pushers 1 1 1 1 2 2

Push time, seconds 60 60 60 45 60 45

Scraper cycle time, seconds 300 300 300 275 300 275

Scraper waiting time for pusher 60 – – – – –

Pusher cycle time, seconds 120 120 100 90 120 90

Size of load, cubic yards 18 18 18 16 18 16

Loads per 45 minute hour 22.5 18 27 29.5 45 49

Yards per 45 minute hour 405 324 486 472 800 784

Scraper cost @ $50 per hour $150 $100 $150 $150 $250 $250

Pusher cost @ $45 per hour 45 45 45 45 90 90

Equipment cost per hour, total 195 145 195 195 340 340

Cost per cubic yard, cents 48.1 44.8 40.1 41.3 42.5 43.4

FIGURE 8.24 Costs in scraper and pusher cycles.