Page 402 - Moving the Earth_ The Workbook of Excavation

P. 402

BLASTING AND TUNNELING

9.2 THE WORK

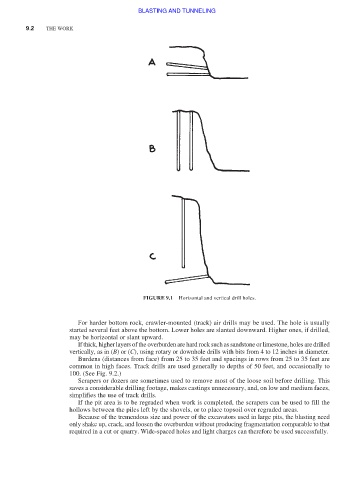

FIGURE 9.1 Horizontal and vertical drill holes.

For harder bottom rock, crawler-mounted (track) air drills may be used. The hole is usually

started several feet above the bottom. Lower holes are slanted downward. Higher ones, if drilled,

may be horizontal or slant upward.

If thick, higher layers of the overburden are hard rock such as sandstone or limestone, holes are drilled

vertically, as in (B) or (C), using rotary or downhole drills with bits from 4 to 12 inches in diameter.

Burdens (distances from face) from 25 to 35 feet and spacings in rows from 25 to 35 feet are

common in high faces. Track drills are used generally to depths of 50 feet, and occasionally to

100. (See Fig. 9.2.)

Scrapers or dozers are sometimes used to remove most of the loose soil before drilling. This

saves a considerable drilling footage, makes castings unnecessary, and, on low and medium faces,

simplifies the use of track drills.

If the pit area is to be regraded when work is completed, the scrapers can be used to fill the

hollows between the piles left by the shovels, or to place topsoil over regraded areas.

Because of the tremendous size and power of the excavators used in large pits, the blasting need

only shake up, crack, and loosen the overburden without producing fragmentation comparable to that

required in a cut or quarry. Wide-spaced holes and light charges can therefore be used successfully.