Page 469 - Moving the Earth_ The Workbook of Excavation

P. 469

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.69

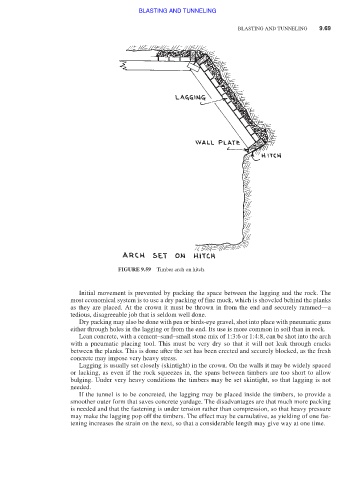

FIGURE 9.59 Timber arch on hitch.

Initial movement is prevented by packing the space between the lagging and the rock. The

most economical system is to use a dry packing of fine muck, which is shoveled behind the planks

as they are placed. At the crown it must be thrown in from the end and securely rammed—a

tedious, disagreeable job that is seldom well done.

Dry packing may also be done with pea or birds-eye gravel, shot into place with pneumatic guns

either through holes in the lagging or from the end. Its use is more common in soil than in rock.

Lean concrete, with a cement–sand–small stone mix of 1:3:6 or 1:4:8, can be shot into the arch

with a pneumatic placing tool. This must be very dry so that it will not leak through cracks

between the planks. This is done after the set has been erected and securely blocked, as the fresh

concrete may impose very heavy stress.

Lagging is usually set closely (skintight) in the crown. On the walls it may be widely spaced

or lacking, as even if the rock squeezes in, the spans between timbers are too short to allow

bulging. Under very heavy conditions the timbers may be set skintight, so that lagging is not

needed.

If the tunnel is to be concreted, the lagging may be placed inside the timbers, to provide a

smoother outer form that saves concrete yardage. The disadvantages are that much more packing

is needed and that the fastening is under tension rather than compression, so that heavy pressure

may make the lagging pop off the timbers. The effect may be cumulative, as yielding of one fas-

tening increases the strain on the next, so that a considerable length may give way at one time.