Page 472 - Moving the Earth_ The Workbook of Excavation

P. 472

BLASTING AND TUNNELING

9.72 THE WORK

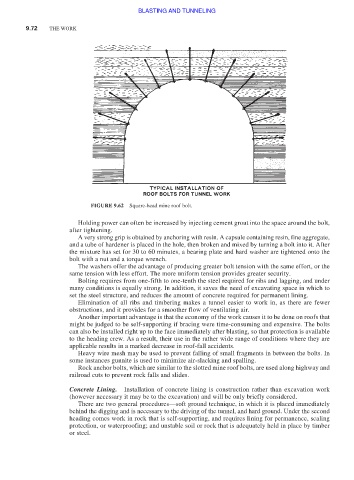

FIGURE 9.62 Square-head mine roof bolt.

Holding power can often be increased by injecting cement grout into the space around the bolt,

after tightening.

A very strong grip is obtained by anchoring with resin. A capsule containing resin, fine aggregate,

and a tube of hardener is placed in the hole, then broken and mixed by turning a bolt into it. After

the mixture has set for 30 to 60 minutes, a bearing plate and hard washer are tightened onto the

bolt with a nut and a torque wrench.

The washers offer the advantage of producing greater bolt tension with the same effort, or the

same tension with less effort. The more uniform tension provides greater security.

Bolting requires from one-fifth to one-tenth the steel required for ribs and lagging, and under

many conditions is equally strong. In addition, it saves the need of excavating space in which to

set the steel structure, and reduces the amount of concrete required for permanent lining.

Elimination of all ribs and timbering makes a tunnel easier to work in, as there are fewer

obstructions, and it provides for a smoother flow of ventilating air.

Another important advantage is that the economy of the work causes it to be done on roofs that

might be judged to be self-supporting if bracing were time-consuming and expensive. The bolts

can also be installed right up to the face immediately after blasting, so that protection is available

to the heading crew. As a result, their use in the rather wide range of conditions where they are

applicable results in a marked decrease in roof-fall accidents.

Heavy wire mesh may be used to prevent falling of small fragments in between the bolts. In

some instances gunnite is used to minimize air-slacking and spalling.

Rock anchor bolts, which are similar to the slotted mine roof bolts, are used along highway and

railroad cuts to prevent rock falls and slides.

Concrete Lining. Installation of concrete lining is construction rather than excavation work

(however necessary it may be to the excavation) and will be only briefly considered.

There are two general procedures—soft ground technique, in which it is placed immediately

behind the digging and is necessary to the driving of the tunnel, and hard ground. Under the second

heading comes work in rock that is self-supporting, and requires lining for permanence, scaling

protection, or waterproofing; and unstable soil or rock that is adequately held in place by timber

or steel.