Page 475 - Moving the Earth_ The Workbook of Excavation

P. 475

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.75

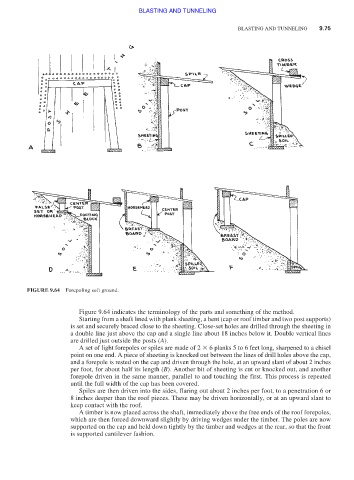

FIGURE 9.64 Forepoling soft ground.

Figure 9.64 indicates the terminology of the parts and something of the method.

Starting from a shaft lined with plank sheeting, a bent (cap or roof timber and two post supports)

is set and securely braced close to the sheeting. Close-set holes are drilled through the sheeting in

a double line just above the cap and a single line about 18 inches below it. Double vertical lines

are drilled just outside the posts (A).

A set of light forepoles or spiles are made of 2 6 planks 5 to 6 feet long, sharpened to a chisel

point on one end. A piece of sheeting is knocked out between the lines of drill holes above the cap,

and a forepole is rested on the cap and driven through the hole, at an upward slant of about 2 inches

per foot, for about half its length (B). Another bit of sheeting is cut or knocked out, and another

forepole driven in the same manner, parallel to and touching the first. This process is repeated

until the full width of the cap has been covered.

Spiles are then driven into the sides, flaring out about 2 inches per foot, to a penetration 6 or

8 inches deeper than the roof pieces. These may be driven horizontally, or at an upward slant to

keep contact with the roof.

A timber is now placed across the shaft, immediately above the free ends of the roof forepoles,

which are then forced downward slightly by driving wedges under the timber. The poles are now

supported on the cap and held down tightly by the timber and wedges at the rear, so that the front

is supported cantilever fashion.