Page 477 - Moving the Earth_ The Workbook of Excavation

P. 477

BLASTING AND TUNNELING

BLASTING AND TUNNELING 9.77

FIGURE 9.65 Setting liner plates. (By permission from “Practical Tunnel

Driving” by Richardson & Mayo, McGraw-Hill.)

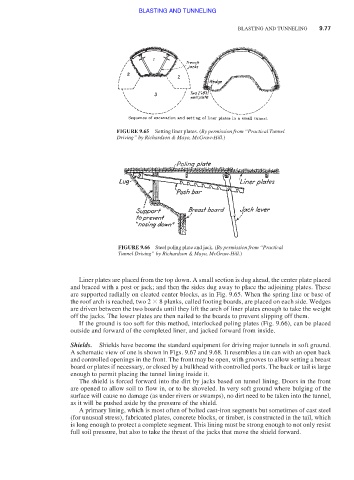

FIGURE 9.66 Steel poling plate and jack. (By permission from “Practical

Tunnel Driving” by Richardson & Mayo, McGraw-Hill.)

Liner plates are placed from the top down. A small section is dug ahead, the center plate placed

and braced with a post or jack; and then the sides dug away to place the adjoining plates. These

are supported radially on cleated center blocks, as in Fig. 9.65. When the spring line or base of

the roof arch is reached, two 2 8 planks, called footing boards, are placed on each side. Wedges

are driven between the two boards until they lift the arch of liner plates enough to take the weight

off the jacks. The lower plates are then nailed to the boards to prevent slipping off them.

If the ground is too soft for this method, interlocked poling plates (Fig. 9.66), can be placed

outside and forward of the completed liner, and jacked forward from inside.

Shields. Shields have become the standard equipment for driving major tunnels in soft ground.

A schematic view of one is shown in Figs. 9.67 and 9.68. It resembles a tin can with an open back

and controlled openings in the front. The front may be open, with grooves to allow setting a breast

board or plates if necessary, or closed by a bulkhead with controlled ports. The back or tail is large

enough to permit placing the tunnel lining inside it.

The shield is forced forward into the dirt by jacks based on tunnel lining. Doors in the front

are opened to allow soil to flow in, or to be shoveled. In very soft ground where bulging of the

surface will cause no damage (as under rivers or swamps), no dirt need to be taken into the tunnel,

as it will be pushed aside by the pressure of the shield.

A primary lining, which is most often of bolted cast-iron segments but sometimes of cast steel

(for unusual stress), fabricated plates, concrete blocks, or timber, is constructed in the tail, which

is long enough to protect a complete segment. This lining must be strong enough to not only resist

full soil pressure, but also to take the thrust of the jacks that move the shield forward.