Page 470 - Moving the Earth_ The Workbook of Excavation

P. 470

BLASTING AND TUNNELING

9.70 THE WORK

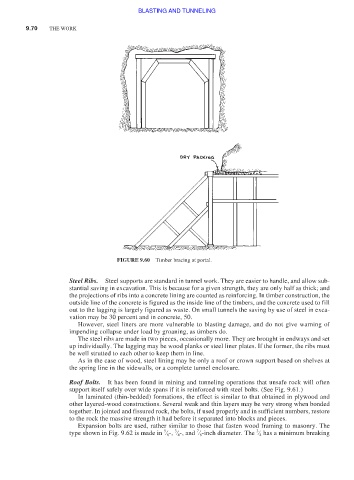

FIGURE 9.60 Timber bracing at portal.

Steel Ribs. Steel supports are standard in tunnel work. They are easier to handle, and allow sub-

stantial saving in excavation. This is because for a given strength, they are only half as thick; and

the projections of ribs into a concrete lining are counted as reinforcing. In timber construction, the

outside line of the concrete is figured as the inside line of the timbers, and the concrete used to fill

out to the lagging is largely figured as waste. On small tunnels the saving by use of steel in exca-

vation may be 30 percent and in concrete, 50.

However, steel liners are more vulnerable to blasting damage, and do not give warning of

impending collapse under load by groaning, as timbers do.

The steel ribs are made in two pieces, occasionally more. They are brought in endways and set

up individually. The lagging may be wood planks or steel liner plates. If the former, the ribs must

be well strutted to each other to keep them in line.

As in the case of wood, steel lining may be only a roof or crown support based on shelves at

the spring line in the sidewalls, or a complete tunnel enclosure.

Roof Bolts. It has been found in mining and tunneling operations that unsafe rock will often

support itself safely over wide spans if it is reinforced with steel bolts. (See Fig. 9.61.)

In laminated (thin-bedded) formations, the effect is similar to that obtained in plywood and

other layered-wood constructions. Several weak and thin layers may be very strong when bonded

together. In jointed and fissured rock, the bolts, if used properly and in sufficient numbers, restore

to the rock the massive strength it had before it separated into blocks and pieces.

Expansion bolts are used, rather similar to those that fasten wood framing to masonry. The

3

7

3

5

type shown in Fig. 9.62 is made in ⁄ 8 -, ⁄ 4 -, and ⁄ 8 -inch diameter. The ⁄ 4 has a minimum breaking