Page 502 - Moving the Earth_ The Workbook of Excavation

P. 502

PIT OPERATION

10.8 THE WORK

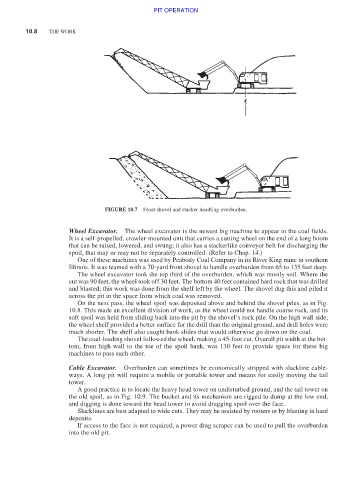

FIGURE 10.7 Front shovel and stacker handling overburden.

Wheel Excavator. The wheel excavator is the newest big machine to appear in the coal fields.

It is a self-propelled, crawler-mounted unit that carries a cutting wheel on the end of a long boom

that can be raised, lowered, and swung; it also has a stackerlike conveyor belt for discharging the

spoil, that may or may not be separately controlled. (Refer to Chap. 14.)

One of these machines was used by Peabody Coal Company in its River King mine in southern

Illinois. It was teamed with a 70-yard front shovel to handle overburden from 65 to 135 feet deep.

The wheel excavator took the top third of the overburden, which was mostly soil. Where the

cut was 90 feet, the wheel took off 30 feet. The bottom 40 feet contained hard rock that was drilled

and blasted; this work was done from the shelf left by the wheel. The shovel dug this and piled it

across the pit in the space from which coal was removed.

On the next pass, the wheel spoil was deposited above and behind the shovel piles, as in Fig.

10.8. This made an excellent division of work, as the wheel could not handle coarse rock, and its

soft spoil was held from sliding back into the pit by the shovel’s rock pile. On the high wall side,

the wheel shelf provided a better surface for the drill than the original ground, and drill holes were

much shorter. The shelf also caught bank slides that would otherwise go down on the coal.

The coal-loading shovel followed the wheel, making a 45-foot cut. Overall pit width at the bot-

tom, from high wall to the toe of the spoil bank, was 130 feet to provide space for these big

machines to pass each other.

Cable Excavator. Overburden can sometimes be economically stripped with slackline cable-

ways. A long pit will require a mobile or portable tower and means for easily moving the tail

tower.

A good practice is to locate the heavy head tower on undisturbed ground, and the tail tower on

the old spoil, as in Fig. 10.9. The bucket and its mechanism are rigged to dump at the low end,

and digging is done toward the head tower to avoid dragging spoil over the face.

Slacklines are best adapted to wide cuts. They may be assisted by rooters or by blasting in hard

deposits.

If access to the face is not required, a power drag scraper can be used to pull the overburden

into the old pit.