Page 507 - Moving the Earth_ The Workbook of Excavation

P. 507

PIT OPERATION

PIT OPERATION 10.13

It is usual for both stripping and extracting operations to be carried on through most of the life

of a pit, either at the same time or alternately. In the Mesabi iron mines the same equipment that

digs ore in the summer loads overburden in the winter. Gravel pits do their stripping in slack sea-

sons, whenever they occur.

Some mines blast and load their own ore but let contracts for stripping off waste, so that the

two jobs are active side by side through the whole working year.

The relative rates of stripping and mining are an important factor in mine efficiency. When

stripping is well ahead, the mine has plenty of working space, with wide bench floors. If mining

is faster than stripping, benches narrow and space becomes crowded, reducing efficiency.

The size of the pay formation may change during mining. Additional reserves may be located,

or the cutoff point between usable material and waste may be changed by variations in price, pro-

cessing methods, or market. Any extension of mining will probably make it necessary to extend

the stripping. However, abandonment of part of the project cannot unstrip the affected area, or

recoup any part of its substantial cost.

A lag in stripping is often due to lack of funds, or to reluctance to invest them any sooner than

is absolutely necessary.

Stripping Costs. Stripping costs are affected by the type and amount of material to be removed,

the distance it must be hauled, grades on the haul route, and efficiency of the operation. These costs

would include all loading and hauling costs as well as supervision, but not drilling and blasting.

Scrapers can move suitable material at 50 to 60 percent of the cost of shovels and trucks, if condi-

tions favor them. But in coarse and rough material their production goes down and costs go up rapidly.

Hydraulicking and dredging are limited to soft overburden, abundant water supply, and dumps

suitable for ponding hydraulic fill. However, if conditions are right, they can remove overburden

as cheaply as any method.

Rail haulage is likely to be cheaper than truck haulage if large volumes are to be moved more

than 2 miles.

Small pits may be able to sell or use their overburden, medium sizes may have little difficulty

finding places to dump it, and large operations may find considerable difficulty in finding ade-

quate disposal areas. For this reason, large-volume stripping may show a higher cost per yard than

small-volume, because of the longer hauls needed.

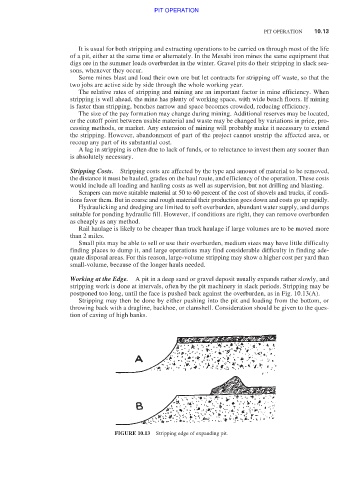

Working at the Edge. A pit in a deep sand or gravel deposit usually expands rather slowly, and

stripping work is done at intervals, often by the pit machinery in slack periods. Stripping may be

postponed too long, until the face is pushed back against the overburden, as in Fig. 10.13(A).

Stripping may then be done by either pushing into the pit and loading from the bottom, or

throwing back with a dragline, backhoe, or clamshell. Consideration should be given to the ques-

tion of caving of high banks.

FIGURE 10.13 Stripping edge of expanding pit.