Page 86 - Moving the Earth_ The Workbook of Excavation

P. 86

SURVEYS AND MEASUREMENTS

2.36 THE WORK

Construction Uses. In earthmoving, the main uses of GPS for machine guidance are for grade

control on dozers, scrapers, and motor graders. Traditionally, the transfer of engineering design

from the drawing board or computer design to the field has relied on the accurate placement of

stakes by survey teams. With the use of centimeter-accuracy guidance on board the earthmoving

machine, the operator can visualize the position of cut-and-fill surfaces in relation to the earth-

work design. This allows a complete digital link from design to layout and reduces the time for

which expensive machines stand idle or need to move the earth material a second time. Moreover,

real-time information can be obtained on the location and productivity of earthmoving equipment,

allowing improved management of the construction site.

GRADING INSTRUMENTS ON EQUIPMENT

As mentioned above, instruments with laser controls and GPS referencing are attached to equipment

like excavators and graders. An extensive array of these devices is produced by the Topcon man-

ufacturers. Also Leica Geosystems has their make of equipment called GradeStar for 3D grading

solutions.

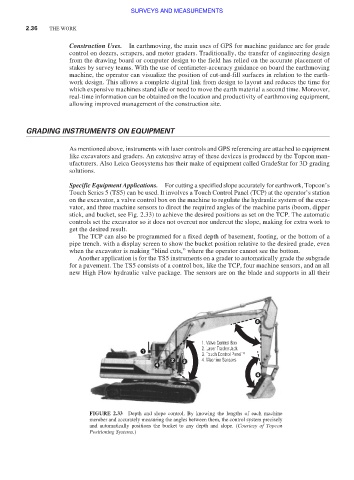

Specific Equipment Applications. For cutting a specified slope accurately for earthwork, Topcon’s

Touch Series 5 (TS5) can be used. It involves a Touch Control Panel (TCP) at the operator’s station

on the excavator, a valve control box on the machine to regulate the hydraulic system of the exca-

vator, and three machine sensors to direct the required angles of the machine parts (boom, dipper

stick, and bucket, see Fig. 2.33) to achieve the desired positions as set on the TCP. The automatic

controls set the excavator so it does not overcut nor undercut the slope, making for extra work to

get the desired result.

The TCP can also be programmed for a fixed depth of basement, footing, or the bottom of a

pipe trench. with a display screen to show the bucket position relative to the desired grade, even

when the excavator is making “blind cuts,” where the operator cannot see the bottom.

Another application is for the TS5 instruments on a grader to automatically grade the subgrade

for a pavement. The TS5 consists of a control box, like the TCP, four machine sensors, and an all

new High Flow hydraulic valve package. The sensors are on the blade and supports in all their

FIGURE 2.33 Depth and slope control. By knowing the lengths of each machine

member and accurately measuring the angles between them, the control system precisely

and automatically positions the bucket to any depth and slope. (Courtesy of Topcon

Positioning Systems.)