Page 7 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 7

Guo, Boyun / Petroleum Production Engineering, A Computer-Assisted Approach Guo-prelims Final Proof page xv 29.12.2006 10:39am

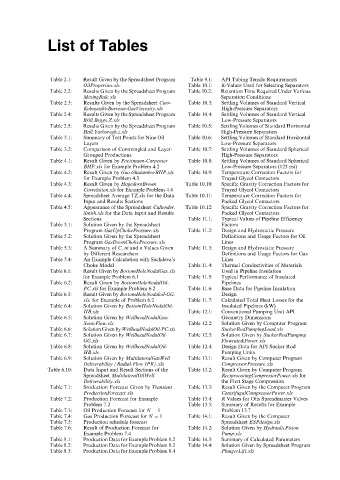

List of Tables

Table 2.1: Result Given by the Spreadsheet Program Table 9.1: API Tubing Tensile Requirements

OilProperties.xls Table 10.1: K-Values Used for Selecting Separators

Table 2.2: Results Given by the Spreadsheet Program Table 10.2: Retention Time Required Under Various

MixingRule.xls Separation Conditions

Table 2.3: Results Given by the Spreadsheet Carr- Table 10.3: Settling Volumes of Standard Vertical

Kobayashi-Burrows-GasViscosity.xls High-Pressure Separators

Table 2.4: Results Given by the Spreadsheet Program Table 10.4: Settling Volumes of Standard Vertical

Brill.Beggs.Z.xls Low-Pressure Separators

Table 2.5: Results Given by the Spreadsheet Program Table 10.5: Settling Volumes of Standard Horizontal

Hall.Yarborogh.z.xls High-Pressure Separators

Table 3.1: Summary of Test Points for Nine Oil Table 10.6: Settling Volumes of Standard Horizontal

Layers Low-Pressure Separators

Table 3.2: Comparison of Commingled and Layer- Table 10.7: Settling Volumes of Standard Spherical

Grouped Productions High-Pressure Separators

Table 4.1: Result Given by Poettmann-Carpenter Table 10.8: Settling Volumes of Standard Spherical

BHP.xls for Example Problem 4.2 Low-Pressure Separators (125 psi)

Table 4.2: Result Given by Guo.GhalamborBHP.xls Table 10.9: Temperature Correction Factors for

for Example Problem 4.3 Trayed Glycol Contactors

Table 4.3: Result Given by HagedornBrown Table 10.10: Specific Gravity Correction Factors for

Correlation.xls for Example Problem 4.4 Trayed Glycol Contactors

Table 4.4: Spreadsheet Average TZ.xls for the Data Table 10.11: Temperature Correction Factors for

Input and Results Sections Packed Glycol Contactors

Table 4.5: Appearance of the Spreadsheet Cullender. Table 10.12: Specific Gravity Correction Factors for

Smith.xls for the Data Input and Results Packed Glycol Contactors

Sections Table 11.1: Typical Values of Pipeline Efficiency

Table 5.1: Solution Given by the Spreadsheet Factors

Program GasUpChokePressure.xls Table 11.2: Design and Hydrostatic Pressure

Table 5.2: Solution Given by the Spreadsheet Definitions and Usage Factors for Oil

Program GasDownChokePressure.xls Lines

Table 5.3: A Summary of C, m and n Values Given Table 11.3: Design and Hydrostatic Pressure

by Different Researchers Definitions and Usage Factors for Gas

Table 5.4: An Example Calculation with Sachdeva’s Lines

Choke Model Table 11.4: Thermal Conductivities of Materials

Table 6.1: Result Given by BottomHoleNodalGas.xls Used in Pipeline Insulation

for Example Problem 6.1 Table 11.5: Typical Performance of Insulated

Table 6.2: Result Given by BottomHoleNodalOil- Pipelines

PC.xls for Example Problem 6.2 Table 11.6: Base Data for Pipeline Insulation

Table 6.3: Result Given by BottomHoleNodaloil-GG. Design

xls. for Example of Problem 6.2 Table 11.7: Calculated Total Heat Losses for the

Table 6.4: Solution Given by BottomHoleNodalOil- Insulated Pipelines (kW)

HB.xls Table 12.1: Conventional Pumping Unit API

Table 6.5: Solution Given by WellheadNodalGas- Geometry Dimensions

SonicFlow.xls. Table 12.2: Solution Given by Computer Program

Table 6.6: Solution Given by WellheadNodalOil-PC.xls SuckerRodPumpingLoad.xls

Table 6.7: Solution Given by WellheadNodalOil- Table 12.3: Solution Given by SuckerRodPumping

GG.xls Flowrate&Power.xls

Table 6.8: Solution Given by WellheadNodalOil- Table 12.4: Design Data for API Sucker Rod

HB.xls. Pumping Units

Table 6.9: Solution Given by MultilateralGasWell Table 13.1: Result Given by Computer Program

Deliverability (Radial-Flow IPR).xls CompressorPressure.xls

Table 6.10: Data Input and Result Sections of the Table 13.2: Result Given by Computer Program

Spreadsheet MultilateralOilWell ReciprocatingCompressorPower.xls for

Deliverability.xls the First Stage Compression

Table 7.1: Sroduction Forecast Given by Transient Table 13.3: Result Given by the Computer Program

ProductionForecast.xls CentrifugalCompressorPower.xls

Table 7.2: Production Forecast for Example Table 13.4: R Values for Otis Spreadmaster Valves

Problem 7.2 Table 13.5: Summary of Results for Example

Table 7.3: Oil Production Forecast for N ¼ 1 Problem 13.7

Table 7.4: Gas Production Forecast for N ¼ 1 Table 14.1: Result Given by the Computer

Table 7.5: Production schedule forecast Spreadsheet ESPdesign.xls

Table 7.6: Result of Production Forecast for Table 14.2: Solution Given by HydraulicPiston

Example Problem 7.4 Pump.xls

Table 8.1: Production Data for Example Problem 8.2 Table 14.3: Summary of Calculated Parameters

Table 8.2: Production Data for Example Problem 8.3 Table 14.4: Solution Given by Spreadsheet Program

Table 8.3: Production Data for Example Problem 8.4 PlungerLift.xls