Page 307 -

P. 307

OXIDATION AND DISINFECTION 10.49

• Operating pressure = 200 to 300 psig (1,379 to 2,068 kPa): medium or high pressure

• Operating pressure = 600 psig (4,137 kPa): high pressure

LOX storage tanks absorb ambient heat, which causes some of the stored liquid prod-

uct to evaporate. The evaporated oxygen gas must be vented or routed to an ozone gen-

erator to prevent overpressurizing the tanks. Depending on tank size, about 0.2% to 0.5%

per day of stored liquid oxygen will vaporize.

On-site storage capacity varies depending on the relative availability of LOX. Most

installations should be provided with at least twice the expected delivery size, which is

typically 5,000 lb (2,268 kg), so that it will not be necessary to deplete the supply on hand

before taking a full delivery.

Vaporizers. The stored LOX must be vaporized to be used. Vaporization is accom-

plished by using water, electricity, steam, liquid petroleum gas (LPG), natural gas, or an

ambient-type vaporizer. The water-type vaporizer uses a water-to-LOX heat exchanger.

Filtered and disinfected water should be used to prevent plugging of the vaporizer. To re-

duce water use, cooling water returned from the ozone generator can be used to supply

the water-type vaporizer. To meet instantaneous oxygen demands with stored LOX, an

uninterrupted water supply is required.

The electric vaporizer uses an immersion-type electric heater submerged in a concrete

basin filled with water. The heater raises the water temperature, and the heat is transferred

to a submerged stainless steel or copper coil where LOX is vaporized to oxygen gas

(GOX). This method requires about 80 kWh to maintain the safer temperature and about

120 kWh per ton of oxygen vaporized.

The steam-type vaporizer uses a steam-to-oxygen heat exchanger and requires ap-

proximately 350 lb (159 kg) of steam per ton of oxygen produced.

The ambient-type vaporizer is a radiator-type vaporizer using ambient heat to vapor-

ize LOX. This type of vaporizer consumes the least amount of energy but requires more

space. At 100,000 ft3/min (2,830 m3/min) vaporization capacity, the space required for

the ambient-type vaporizer is about 36 by 14 ft (11 by 4 m). However, a fan can be pro-

vided to increase ambient airflow and reduce the size of the vaporizer. In addition, a heater

is sometimes provided to prevent the vaporizer from freezing.

The LPG/natural gas vaporizer is a direct-fire vaporizer using LPG (such as propane)

or natural gas to power a water heater and a water recirculation system. The heated wa-

ter vaporizes LOX to GOX. This type of vaporizer can provide an uninterrupted oxygen

supply from the storage tanks during plant power outage. If LPG is used as the primary

fuel, a storage vessel is required. For safety reasons, this type of vaporizer should be lo-

cated remote from the LOX storage tanks. The different types of vaporizers are compared

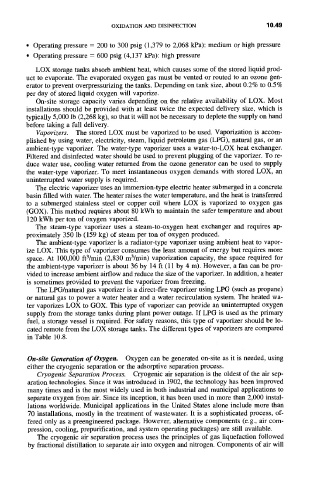

in Table 10.8.

On-site Generation of Oxygen. Oxygen can be generated on-site as it is needed, using

either the cryogenic separation or the adsorptive separation process.

Cryogenic Separation Process. Cryogenic air separation is the oldest of the air sep-

aration technologies. Since it was introduced in 1902, the technology has been improved

many times and is the most widely used in both industrial and municipal applications to

separate oxygen from air. Since its inception, it has been used in more than 2,000 instal-

lations worldwide. Municipal applications in the United States alone include more than

70 installations, mostly in the treatment of wastewater. It is a sophisticated process, of-

fered only as a preengineered package. However, alternative components (e.g., air com-

pression, cooling, prepurification, and system operating packages) are still available.

The cryogenic air separation process uses the principles of gas liquefaction followed

by fractional distillation to separate air into oxygen and nitrogen. Components of air will